You pull a batch of beautiful Yunnan beans from the roaster. They smell amazing, but the yield feels light. Your spreadsheet says you should have 20 kg of roasted coffee, but the scale tells a different story. That gap isn't just missing product; it's disappearing profit. Calculating roast loss percentage isn't just a quality control step—it's the fundamental math that determines your true cost per pound, your selling price, and ultimately, your business margin. Doing it incorrectly is like flying blind.

So, what's the correct method? Roast loss percentage is calculated by measuring the weight of green coffee before roasting and the weight of roasted coffee after cooling, then applying this formula: ((Green Weight - Roasted Weight) / Green Weight) x 100.

The critical nuance, however, lies in the strict protocols for weighing, cooling, and accounting for moisture. A small error in process can lead to a significant miscalculation in your loss figure, misleading your entire financial model.

At BeanofCoffee, we understand this from both sides of the supply chain. As producers of consistent, high-density green beans, we know that predictable roast loss is a key feature of our product for professional roasters. We help our clients establish accurate baselines so they can trust their numbers. Let's break down the exact steps to move from a casual estimate to a precise, repeatable calculation you can bank on.

What is the Step-by-Step Process for Accurate Measurement?

Precision is a process, not a single action. To get a true roast loss percentage, you must control every variable in the weighing chain. Here is the industry-standard protocol:

- Weigh the Green Coffee: Tare your scale with the empty roasting drum or charge bin. Weigh the exact amount of green coffee you are charging into the roaster. Record this weight (e.g., 5000.0g). Use a scale with at least 1g resolution.

- Roast to Your Target Profile: Conduct the roast as normal.

- Cool the Coffee Completely: This is non-negotiable. Transfer the roasted beans to your cooler and run the cycle until the beans are truly at ambient temperature. Warm beans are still off-gassing moisture and CO2, which skews weight.

- Weigh the Roasted & Cooled Coffee: Tare your scale with an empty, clean container. Transfer all the cooled beans from the cooler and weigh them. Record this weight (e.g., 4200.0g).

- Apply the Formula: Use the recorded weights in the standard formula.

- Loss = Green Weight - Roasted Weight → 5000g - 4200g = 800g

- Loss Percentage = (Loss / Green Weight) x 100 → (800 / 5000) x 100 = 16%

This 16% is your true yield from that batch. Deviating from this process—like weighing warm beans—is the most common source of error.

Why is Complete Cooling an Absolute Requirement?

Weighing warm coffee is the single biggest mistake in loss calculation. Here's why: During roasting, water turns to steam and escapes. When you drop the beans, they are still hot and releasing that steam (along with CO2). If you weigh them immediately, you are capturing a weight that is still decreasing. The beans might lose another 0.5% to 1% of their weight as they finish cooling to room temperature. This error makes your loss percentage appear smaller than it really is, tricking you into thinking your yield is higher. It directly corrupts your cost analysis. Always wait until the beans are cool to the touch, typically 5-10 minutes after the cooling cycle ends in a professional cooler.

How Should You Handle Chaff and Fines Loss?

This is a key decision point for accuracy. Chaff (silverskin) accounts for a portion of the weight loss. Some roasters include it in the calculation by weighing the total roasted output including any chaff that remains mixed with the beans (which is minimal). Others deliberately separate and exclude chaff. The most consistent and recommended method is to weigh the roasted beans as they come out of the cooler, with the chaff that naturally remains with them. Do not actively blow it off. This represents the actual salable product you have. If you have a separate collection system for fines (small broken particles), those should be included in the roasted weight as they are still part of the product, even if lower grade. Consistency in your method is more important than the minor variation between methods.

What Factors Influence Roast Loss Percentage?

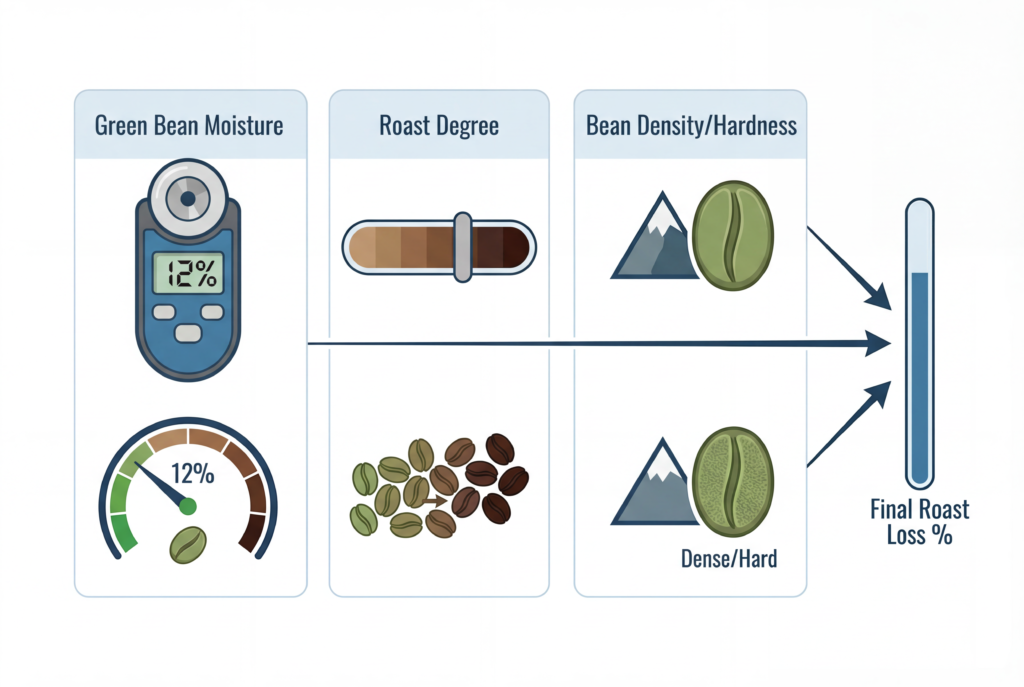

Roast loss isn't a fixed number; it's an outcome. Understanding the variables allows you to control them. The primary drivers are:

- Moisture Content of the Green Bean: This is the #1 factor. Green coffee typically has 10-12% moisture by weight. Most of this water is driven off during roasting. A higher moisture content directly leads to a higher roast loss. This is why knowing the moisture content of your green coffee from your supplier is critical.

- Roast Degree (Development Time & Temperature): Darker roasts lose more weight. Longer roasting times and higher end temperatures drive off more water and cause more pyrolysis (thermal decomposition) of organic matter, increasing loss. A light roast may lose 12-14%, while a dark espresso roast can lose 18-22%.

- Bean Density and Hardness: Dense, hard bean (SHB) coffee from high altitudes like our Yunnan Arabica has a tighter cellular structure. It often retains slightly more mass through the roast compared to a less dense, soft bean, all else being equal, potentially resulting in a marginally better yield.

- Roaster Type and Efficiency: The airflow and heat transfer of your specific roaster can influence how efficiently moisture is removed.

Think of roast loss as the bill for the transformation you're paying for. You're trading water and mass for flavor development.

How Does Green Coffee Moisture Content Directly Impact Loss?

The relationship is almost linear. If your green coffee has 11% moisture and you roast it to a medium profile, you can expect nearly all of that moisture (minus a small residual amount) to be lost. That's already an 11% loss before accounting for the loss of dry matter (fiber, sugars) during pyrolysis. A batch with 10% moisture will inherently have about 1% less loss than a batch with 11% moisture, assuming the same roast profile. This is why working with a supplier who provides consistent, measured moisture content—like BeanofCoffee—is a direct input into your predictable financials. It removes a major variable. You can use a moisture meter for coffee to verify incoming green coffee.

How Can You Use Roast Profiles to Manage Yield vs. Flavor?

This is the roaster's core dilemma: flavor vs. yield. Pushing for a lower loss (better yield) by roasting faster and lighter might preserve mass but result in underdeveloped, grassy flavors. Chasing a specific flavor profile by extending development time will increase loss (lower yield). The key is to establish a "sweet spot" profile for each coffee that achieves your target flavor while making the associated loss predictable and acceptable. You then build that loss percentage into your cost model. For example, if our Yunnan Catimor yields a perfect flavor at a 16% loss, you price your roasted coffee knowing that 1 kg of green yields 840g of roasted product. You manage for consistency, not for arbitrarily low loss.

How Do You Use Roast Loss Data in Pricing and Costing?

This is where the math turns into money. Accurate loss percentage is the bridge between your green coffee cost and your finished product cost.

The Basic Costing Formula:

Cost per Roasted Kg = (Cost per Green Kg) / (1 - Loss Percentage)

Example:

- You buy our Yunnan Arabica for $6.00 per kg (green).

- Your consistent roast loss for this coffee is 16% (or 0.16).

- Cost per Roasted Kg = $6.00 / (1 - 0.16) = $6.00 / 0.84 = $7.14 per kg.

That $7.14 is your true landed cost for the roasted coffee before you even factor in labor, packaging, overhead, and profit. If you had incorrectly used a 14% loss, your cost would be $6.98/kg, underpricing your product and eroding your margin by $0.16 per kg. At scale, this error is catastrophic.

What Should a Roast Log Include for Financial Tracking?

Your roast log should be a combined quality and financial document. For each batch, record:

- Batch ID / Date

- Green Coffee Origin & Lot (e.g., BeanofCoffee Yunnan Catimor Lot #123)

- Green Charge Weight (g or kg)

- Roasted/Cooled Output Weight (g or kg)

- Calculated Loss Percentage

- Roast Profile Notes (time to first crack, end temp, total time)

- Moisture Content of Green (if known)

Tracking this over time for each coffee gives you a reliable average loss percentage to use in your standard costing models. It also helps you identify anomalies—like a sudden spike in loss—that could indicate a change in the green coffee or an issue with your roaster.

How Can Consistent Green Coffee Minimize Financial Variance?

This is the ultimate argument for working with a reliable supplier. Inconsistent green coffee—with fluctuating moisture content, density, and screen size—leads to inconsistent roast loss. One batch loses 15%, the next 17%. Your production cost becomes unpredictable, and your pricing either becomes inaccurate or must include a buffer for the worst-case loss scenario, making you less competitive.

When you source from BeanofCoffee, you get consistency: consistent moisture (targeted at 10-12%), consistent density (Strictly Hard Bean), and consistent processing. This allows you to establish one trusted, accurate loss percentage for that coffee. You can then price confidently, manage inventory precisely, and predict your gross margin. This stability is a tangible financial benefit of a trustworthy partnership.

Conclusion

Correctly calculating roast loss percentage is a non-negotiable discipline for any professional roasting operation. It transcends quality control to become the bedrock of your profitability. The correct method demands strict adherence to weighing cooled coffee and applying the simple formula, but the real value comes from understanding the factors that influence loss and using that data to make informed financial and roasting decisions.

Mastering this process turns roasting from an art into a manageable science, where every gram is accounted for and every flavor decision has a known cost.

At BeanofCoffee, we provide the consistent, measurable green coffee that makes precise roast loss calculation possible. Our detailed spec sheets provide the baseline data you need to build accurate and profitable roasting models.

To discuss how our consistent Yunnan Arabica can bring predictability to your roast yields and costing, contact our sales lead, Cathy Cai. Request spec sheets and samples at cathy@beanofcoffee.com.