So, you've secured a fantastic batch of premium Yunnan coffee, but now comes a crucial step that can make or break its journey to your overseas customer: selecting the right container liner. An improper liner choice can lead to moisture damage, flavor contamination, and significant financial loss. This is about protecting not just a product, but your reputation for delivering "safe, reliable, stable, and trustworthy" quality.

Choosing the right liner for coffee shipping hinges on creating a multi-layered barrier against moisture, physical contaminants, and condensation. The optimal choice balances protection, cost, and practicality, often combining materials like food-grade plastic liners with absorbent paperboard dunnage and desiccants to ensure your beans arrive in perfect condition. For large-volume export, this system is your final, critical line of defense.

Let's navigate the practicalities of container liners, moving beyond theory to the concrete steps that safeguard your coffee across oceans.

What Are the Main Types of Liners for Coffee Container Shipping?

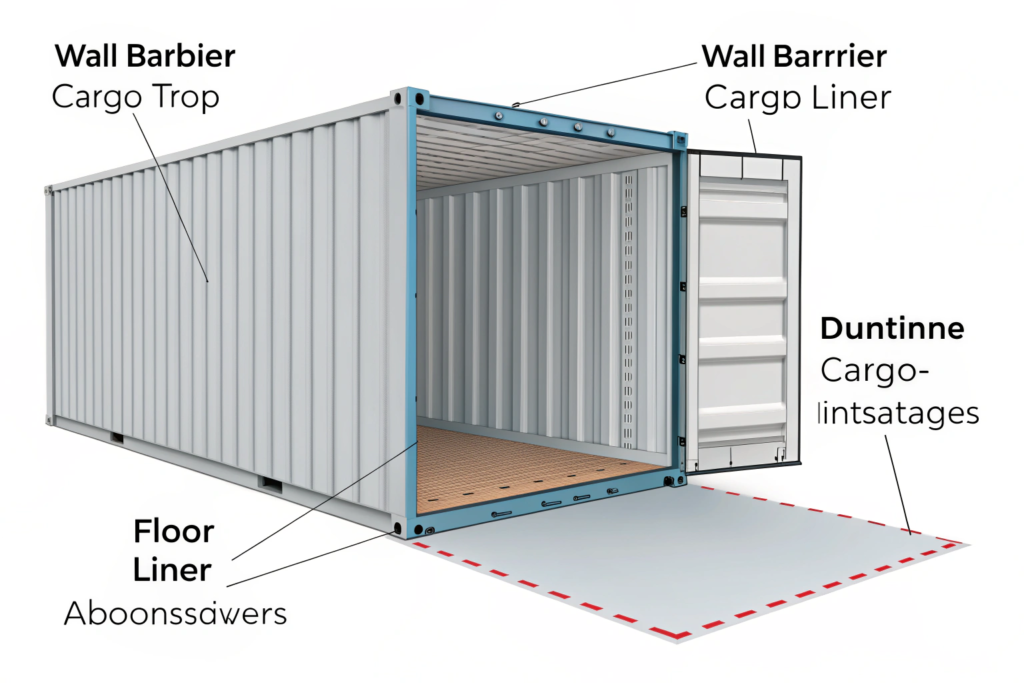

When we talk about "liners," we're really discussing a system of complementary materials that work together inside the container. The goal isn't just to line the walls—it's to manage the entire micro-environment your coffee will inhabit for weeks. There are four key components to consider, each with a distinct role in your protection strategy.

The primary barrier is the wall and floor liner, which physically separates your cargo from the container's interior. Then comes the dunnage or top liner, which protects against overhead condensation and secures the load. Finally, strategic moisture absorbers tackle the humidity that inevitably remains. Each type of material has its strengths, and understanding them is the first step to building an effective shield.

Plastic Barrier Liners vs. Paperboard Dunnage: What's the Core Difference?

This is the fundamental choice. Plastic Barrier Liners (often HDPE or woven PP) are your continuous, impermeable shield. They are installed against the container walls and floor to create a bag-like environment, directly blocking external moisture and preventing contact with any rust or residues. They are essential for creating a primary moisture barrier.

In contrast, Paperboard Dunnage (like heavy-duty corrugated board) serves a different, vital purpose. It is not typically a full-wall liner but is used as a top dunnage layer placed over the last row of bags . Its key functions are to absorb any dripping condensation from the container roof and to protect the cargo from dirt. It also acts as a spacer to allow air circulation. A patent for a container liner system also describes using double-faced corrugated paperboard panels as a structured, foldable liner that can protect cargo from condensation and contaminants. Often, the most robust approach is to use a plastic liner for the walls and floor, and corrugated paperboard as a top layer.

How Do Desiccants and Absorbers Fit into the Liner System?

Liners manage liquid water and direct contact, but humidity is an invisible threat. This is where desiccants like silica gel or calcium chloride come in. They are not liners themselves, but a mandatory supplement to any liner system. You must strategically hang or place desiccant bags throughout the container space—especially near the door and corners—to actively pull moisture vapor from the air trapped inside your plastic liner envelope. Think of it this way: the plastic liner stops new moisture from getting in, and the desiccants work to reduce the moisture that's already there. Never skip this step. For comprehensive protection, also consider using oxygen absorbers within the individual coffee bags themselves to preserve freshness during the long voyage.

How to Select the Best Liner Material for Your Coffee Type?

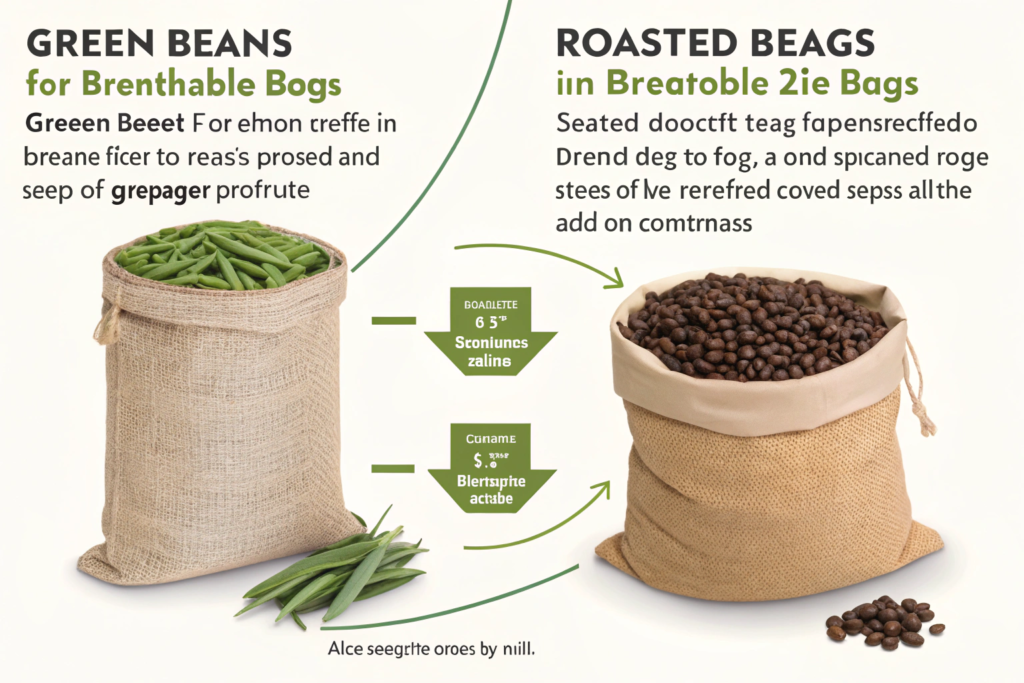

The "best" liner isn't a universal product; it's the one most suited to your specific coffee format, packaging, and journey. Green (unroasted) beans, roasted whole beans, and ground coffee all have different vulnerabilities that your liner strategy must address.

For instance, green beans in breathable jute bags have different needs than roasted beans in sealed foil bags. A one-size-fits-all approach risks either under-protection or unnecessary cost. Your selection should be a calculated response to the specific risks your cargo faces.

What Liner Considerations Are Critical for Green vs. Roasted Beans?

Green Coffee Beans are typically shipped in porous natural fiber bags (like jute or sisal) and are somewhat more resilient but still highly susceptible to moisture and odors. Here, the primary liner focus is on strong moisture and odor barrier. A thick, food-grade plastic liner is non-negotiable to prevent mustiness and mold. Good top dunnage is also critical to manage "container sweat."

Roasted Coffee Beans, especially those pre-packaged for retail, have an additional enemy: oxygen. While the primary packaging (valve bags with nitrogen flush) handles this internally , the container liner's job is to maintain a stable external environment. Any moisture ingress can compromise the outer packaging and accelerate staling. For roasted beans, ensuring your plastic liner is completely sealed and using ample desiccants is paramount to protect the integrity of the consumer packaging.

Does Packaging Format Influence Your Liner Choice?

Absolutely. If you are shipping bulk bags (big bags) of green beans, the physical abrasion resistance of the liner becomes more important. A thicker, woven polypropylene liner might be chosen over a thinner HDPE one. If you are shipping master cartons containing small retail bags, the risk of physical damage from container wall contact is lower, so a standard plastic liner suffices. However, the need for top dunnage to protect against condensation dripping onto the cardboard boxes is very high, as wet cardboard can ruin the presentation and structural integrity of your export units.

What Are the Practical Steps to Install a Container Liner?

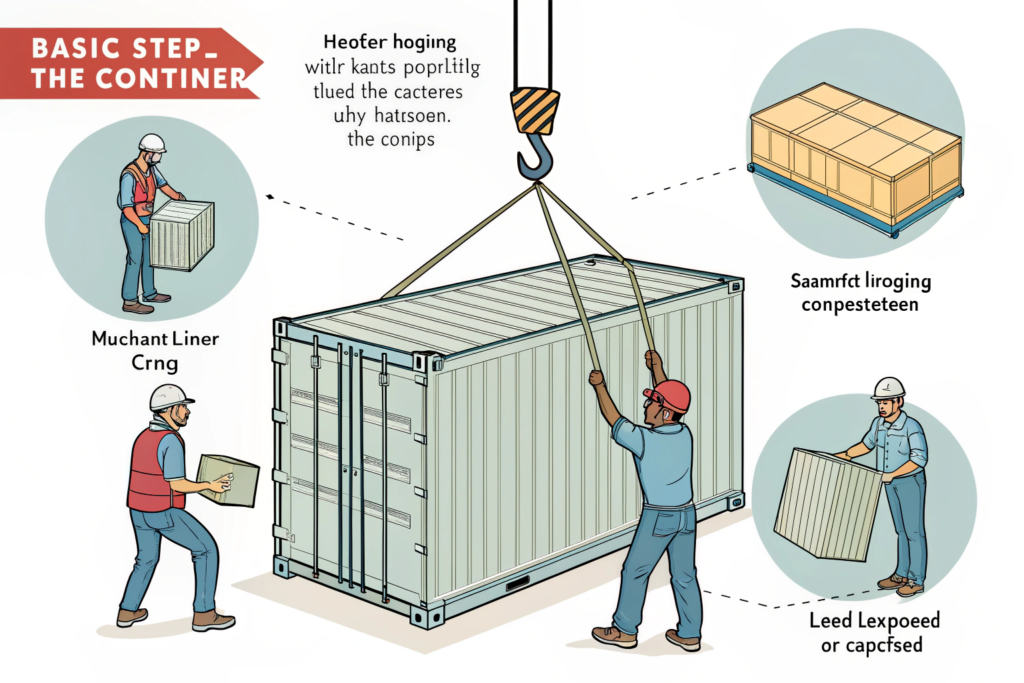

A perfect liner is useless if it's installed poorly. Installation is a hands-on process that requires care and attention to detail. The goal is to create a seamless, enclosed environment within the container.

The basic process involves preparing the container, methodically hanging the liner, securing it properly, and finally loading the cargo in a way that doesn't compromise the system. Rushing this step is a common and costly error.

How Do You Properly Fit and Secure a Plastic Liner?

First, inspect the container for any sharp protrusions, hooks, or remnants of previous cargo that could puncture the liner. Sweep it clean. The liner is typically supplied as a large, folded sack. Unfold it inside the container, starting from the front (door end). Smooth it out against the walls and into the corners. Many liners have reinforced corners or gussets to fit standard container dimensions. The key is to achieve a wrinkle-free fit where possible, as folds can trap moisture or tear. The liner should be secured at the top of the walls, often using a batten tape or specialized adhesive strips provided with the liner kit. The patent for a paperboard liner system notes that a key advantage of such designs is their simplicity and speed of installation, requiring minimal training. The entire floor and walls should be covered.

What Is the Correct Order for Loading with Liners and Dunnage?

Sequence is critical. Follow this standard practice:

- Install the Wall/Floor Liner: Fit your primary plastic liner against the container walls and floor, securing it at the top.

- Place Bottom Dunnage: Before loading cargo, some protocols place a layer of pallets or lumber on the floor (inside the liner) to elevate the coffee off the container floor, enhancing air circulation.

- Load the Cargo: Carefully load your palletized or stacked coffee bags. Avoid over-tight packing; allow for some air movement.

- Install Top Dunnage: Once loading is complete, drape a layer of corrugated paperboard or specialized top liner over the entire top layer of your cargo. This is your shield against condensation.

- Hang Desiccants: Before sealing the liner, strategically hang your desiccant bags from the container's lashing points or the liner itself, ensuring they are suspended in the air space.

- Seal the Liner: Gather the excess liner material at the door end and fold or tie it securely to create a closed environment. Do not pack cargo directly against this sealed end.

How Can You Evaluate and Source Reliable Liner Suppliers?

Your liner is as good as the company that makes and supplies it. For a business built on reliability like Shanghai Fumao, partnering with a trustworthy liner supplier is part of the quality chain.

Look for suppliers with proven experience in food-grade and agricultural shipping. They should understand the specific challenges of coffee and be able to provide technical data sheets for their materials, including moisture vapor transmission rates (MVTR) for plastics and weight specifications for paperboard.

What Key Questions Should You Ask a Potential Liner Supplier?

Go beyond price. Ask these questions to gauge their expertise:

- "Can you provide a certificate of analysis confirming your plastic liner is made from food-grade, odorless resin?"

- "What is the thickness and puncture resistance of your liner material?"

- "Do you offer a complete kit that includes the wall/floor liner, top dunnage, desiccants, and sealing tape?"

- "Can you share case studies or references from other coffee exporters?"

- "What is your lead time, and do you support just-in-time delivery for our shipment schedule?"

What Are the Cost vs. Protection Trade-offs?

The cheapest liner may save pennies per container but risk thousands in damaged goods. Calculate the Total Cost of Protection. A slightly more expensive, higher-specification plastic liner with better MVTR ratings might provide exponentially better moisture protection. Similarly, investing in sufficient, high-capacity desiccants is always cost-effective compared to the loss of even a single bag of coffee. View this not as a packaging cost, but as essential risk mitigation insurance for your valuable cargo. Building a partnership with a quality-focused supplier ultimately protects your bottom line and your brand's promise to customers.

Conclusion

Selecting the right liner for coffee shipping is a deliberate science of layered defense. It requires matching robust plastic barriers and absorbent paperboard dunnage with active desiccants, all installed with precision. This system directly defends against the top threats of moisture, condensation, and contamination, ensuring the premium quality you've cultivated in Yunnan is delivered intact to your international buyers.

By mastering this final logistical step, you transform the shipping container from a potential hazard into a controlled, protective capsule. For partners who value this meticulous attention to detail from plantation to port, we are here to ensure every bean is guarded with the utmost care. To discuss a shipping and liner protocol tailored to your next order of Catimor, Arabica, or Robusta, please contact our logistics specialist, Cathy Cai, at cathy@beanofcoffee.com.