You've just closed a deal for a container of premium Yunnan Arabica from Bean of Coffee. The beans are on the water, and you're excited. But then, reality sets in. Where will you store 20 tons of green coffee? How do you ensure the Ethiopian you roasted last week sells before it goes stale? How much Sumatra should you keep on hand for your best-selling blend? For a roaster, inventory isn't just bags of beans—it's frozen cash, quality risk, and operational chaos waiting to happen. Mismanage it, and you're hit with waste, cash flow shortages, and disappointed customers.

So, how do you manage inventory for a coffee roasting business? Effective management is a dual-track system: treating green coffee as a strategic commodity and roasted coffee as a perishable good. It requires balancing purchase timing, storage science, demand forecasting, and precise tracking. At Bean of Coffee, as suppliers to roasters worldwide, we see that our most successful clients are those who master this discipline. They turn inventory from a liability into a competitive advantage of freshness, variety, and financial health.

Let's walk through the systems and strategies to keep your cash flowing and your coffee at its peak, from the warehouse to the customer's cup.

How to manage green coffee inventory?

Green coffee is your most valuable and volatile asset. It's a commodity whose price can fluctuate, but it's also a perishable agricultural product with a finite shelf life. Your goal is to buy enough to secure good prices and ensure supply, but not so much that it ages beyond its prime or ties up all your capital.

The first rule is to categorize your green coffee. Not all beans are equal in your business. This helps you prioritize purchasing and storage efforts.

What is the ABC analysis for green coffee?

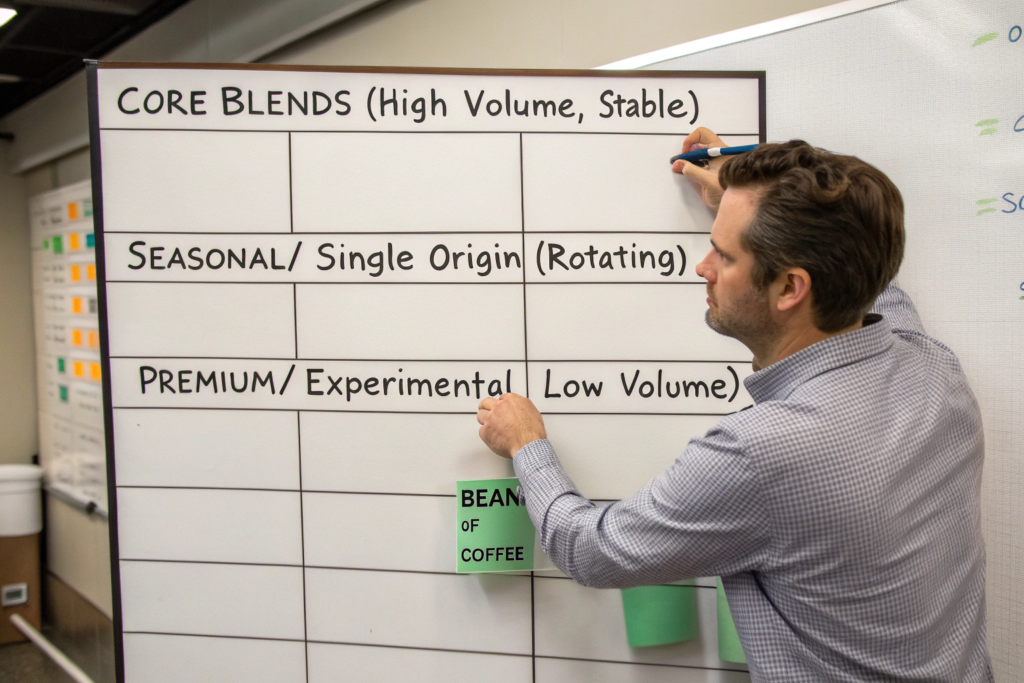

This is a classic inventory technique adapted for coffee. You classify items based on their consumption value (usage rate × cost).

- A-Items (Core Blends): Represent ~20% of your SKUs but account for ~70% of your annual green coffee usage. These are your workhorses—the Brazilian base, the Sumatran for your dark roast, the Yunnan Catimor for your espresso blend. You must have these in stock at all times. For these, you buy in larger quantities (full bags or pallets) to secure better prices from suppliers like us, and you monitor their levels closely.

- B-Items (Seasonal/Single Origins): ~30% of SKUs, ~20% of usage. These are your rotating offerings. You might buy 2-4 bags at a time. The goal is to turn them over within a season.

- C-Items (Premium/Experimental): ~50% of SKUs, ~10% of usage. These are your microlots, geishas, or test batches. You buy minimal quantities (maybe half a bag) to minimize risk and capital tied up.

This analysis tells you where to focus your management efforts and capital. Your "A" items justify a more sophisticated forecasting and reordering system.

How do you calculate reorder points and safety stock for green coffee?

You need a trigger to tell you, "It's time to order more."

- Lead Time Demand: How much coffee will you use during the time it takes to get a new shipment? (e.g., You use 50kg/week of your core Brazilian, and it takes 4 weeks from order to delivery. Lead Time Demand = 200kg).

- Safety Stock: A buffer for unexpected events (a spike in sales, a shipping delay). A common formula is: (Max Weekly Usage × Max Lead Time) – (Average Weekly Usage × Average Lead Time).

- Reorder Point (ROP): The inventory level at which you place a new order. ROP = Lead Time Demand + Safety Stock.

In the example above, if your safety stock is 100kg, your ROP for Brazilian is 300kg. When your stock drops to 300kg, you place an order with your supplier. This prevents stockouts without over-ordering. For origins with longer lead times (like our Yunnan coffee), a higher safety stock is prudent.

How to store green and roasted coffee properly?

Improper storage is where quality and money evaporate. Green coffee can last 12+ months if stored well, but only a few months if stored poorly. Roasted coffee has a shelf life of mere weeks.

The enemies are universal: oxygen, moisture, heat, light, and pests. Your storage solutions must combat all of these.

What are the ideal conditions for green coffee storage?

To preserve freshness and prevent aging or mold:

- Temperature: Cool and stable, ideally between 15-20°C (59-68°F). Avoid heat sources.

- Humidity: Maintain 50-60% relative humidity. Use a dehumidifier in damp climates. Beans are hygroscopic—they absorb moisture from the air.

- Airflow & Containment: Keep beans in their original, sealed bags (GrainPro, multi-layer) until use. Once opened, transfer to airtight, food-grade containers. Store bags on pallets off concrete floors to prevent moisture absorption.

- Pest Control: Implement an integrated pest management (IPM) plan. Rodents and insects (like the coffee borer beetle) can ruin entire lots. Clean, sealed storage is your first defense.

A dedicated, climate-controlled space is not a luxury; it's a necessity for protecting your largest raw material investment.

How should you organize roasted coffee inventory?

Roasted coffee is a race against time. Organization is critical for First-In, First-Out (FIFO) practices.

- Clear Labeling: Every batch must be labeled with the roast date (not just "best by") and the coffee's identity.

- Physical FIFO Flow: Design your shelf layout so that the oldest stock is physically in the front and easiest to grab. New stock goes behind.

- Packaging: Use high-quality bags with one-way degassing valves for retail. For bulk cafe use, use airtight, opaque containers (like Gamma Vaults) and fill them completely to minimize oxygen.

- Shelf-Life Policy: Establish and enforce clear shelf-life limits for your products (e.g., 30 days for retail bags, 7 days for open bulk containers). This is non-negotiable for quality. The Specialty Coffee Association provides guidelines on freshness that can inform your policy.

How to track inventory and forecast demand?

You can't manage what you don't measure. Moving from gut feeling to data-driven decisions is what separates hobbyists from professional businesses. This means implementing a tracking system and learning from sales patterns.

Even a simple system is better than none. Start with a spreadsheet, but plan to graduate to dedicated software as you grow.

What are the key inventory metrics (KPIs) to monitor?

Track these numbers religiously:

- Days of Supply (DOS): (Current Inventory / Average Daily Usage). This tells you how long your current stock will last. For "A" items, you might target 45-60 days of supply. For "C" items, 15-30 days.

- Inventory Turnover Ratio: (Cost of Goods Sold / Average Inventory Value). A higher ratio means you're selling through your inventory quickly, which is good for cash flow and freshness. Aim for a minimum of 6-8 turns per year for green coffee.

- Stockout Rate: How often you run out of an item. Aim for 0% on your "A" items.

- Waste/Shrinkage Rate: (Value of Wasted Coffee / Total Coffee Usage). Track this to identify problems in roasting accuracy, over-purchasing, or expired roasted stock.

How can you forecast demand more accurately?

Forecasting is part art, part science.

- Historical Sales Data: This is your best friend. Analyze sales from the previous year, broken down by month/week. Account for seasonality (cold brew in summer, dark roasts in winter).

- Factor in Growth: Don't just look backward. If sales are growing 10% month-over-month, factor that into your future needs.

- The Pipeline Factor: Know what's coming. Are you launching a new wholesale account? Getting featured in a publication? Adjust forecasts upward.

- Communicate with Sales: If you have a sales team, their pipeline reports are crucial input for your purchasing decisions. For smaller operations, the roaster is often the salesperson—keep your own notes on customer conversations.

What are common inventory pitfalls and how to avoid them?

Even with a system, roasters fall into predictable traps. Being aware of them is the first step to avoidance.

The most common pitfall is the "shiny object" syndrome—buying too much of an exciting new coffee without a sales plan, which then sits and ages.

How to avoid dead stock and aged green coffee?

Dead stock is inventory that hasn't moved in 9-12 months. It ties up capital and space.

- Buy with a Plan: Only purchase a new coffee if you have a specific slot for it in your lineup (e.g., "This will be our new spring single-origin").

- Set Review Dates: Mark your calendar to review slow-moving coffees at 6 months. If they haven't sold, create a promotion: offer it as a limited "brewer's batch," use it in a blend, or sell it at a discount to clear space.

- Sample Before You Commit: Always, always sample before buying a full bag, let alone a pallet. A sample from Bean of Coffee lets you test roast and cup to ensure it fits your needs before you invest.

How to manage cash flow with seasonal demand?

Coffee sales are often seasonal. Your purchasing must reflect this.

- Build Inventory in the Off-Season: When sales are slower (maybe late summer), use the opportunity to buy your core "A" items at good prices. Your cash is less tight then.

- Use Flexible Financing: For large seasonal purchases (like pre-holiday stock), consider trade finance options like a letter of credit or short-term loan to avoid a massive cash outlay. This smooths out your cash flow.

- Communicate with Suppliers: Work with your suppliers. We at Bean of Coffee can often structure deliveries or payment terms to help you manage seasonal peaks, because a successful, growing client is in our best interest too.

Conclusion

Managing inventory for a coffee roasting business is a continuous balancing act between art and science, quality and cost, supply and demand. It requires treating green coffee as a valued commodity with strategic purchasing and pristine storage, while handling roasted coffee as a perishable gem with ruthless FIFO and freshness protocols. Success hinges on data—tracking key metrics, forecasting demand, and using systems to make informed decisions.

By mastering this discipline, you transform inventory from a source of stress and waste into the engine of your business: ensuring you always have the right coffee, at the right time, at its peak of freshness. This builds customer trust, optimizes cash flow, and solidifies your reputation as a reliable, quality-focused roaster.

If managing your green coffee supply chain is a constant challenge, let's build a more predictable partnership. At Bean of Coffee, we offer consistent quality, flexible order sizes, and reliable logistics from our Yunnan farms. We can help you simplify one crucial part of your inventory equation. To discuss a more streamlined supply of Arabica, Catimor, or Robusta for your core blends, contact our export manager, Cathy Cai, at cathy@beanofcoffee.com. Let's stock your success.