You receive an urgent call: your main shipping route is congested, coffee prices just spiked 20%, and your warehouse is running low on your best-selling blend. Meanwhile, customers complain about inconsistent quality. These aren't isolated problems—they're symptoms of a supply chain that hasn't been optimized for today's volatile coffee market. Optimization isn't just about cutting costs; it's about building resilience, ensuring quality, and creating competitive advantage.

Optimizing your coffee supply chain involves integrating technology for visibility, diversifying sourcing to mitigate risk, building collaborative partnerships, implementing lean inventory practices, and establishing rigorous quality control checkpoints. The goal is creating a responsive, transparent chain that delivers consistent quality at competitive costs while adapting to disruptions.

So, where do you start when your supply chain spans continents, involves dozens of partners, and handles a perishable product sensitive to time, temperature, and handling? The most effective approach addresses both strategic relationships and operational processes. Let's examine the key leverage points for creating a coffee supply chain that's efficient, resilient, and quality-focused.

How Can Technology Increase Visibility and Control?

In the coffee chain, information gaps cause more problems than physical gaps. Technology provides the visibility needed to manage complexity and anticipate issues before they become crises.

Modern supply chain technology moves beyond basic tracking to predictive analytics, real-time monitoring, and integrated data sharing among partners.

What Systems Provide Meaningful Visibility?

- IoT Sensors: Monitor temperature/humidity in containers and warehouses

- Blockchain Platforms: Create immutable records from farm to roastery

- ERP Integration: Connect purchasing, inventory, production, and sales data

- Predictive Analytics: Forecast demand, price movements, and potential disruptions

- Supplier Portals: Enable transparent communication and document sharing

At BeanofCoffee, we provide partners with access to our traceability platform, showing real-time shipment status and quality documentation. This shared visibility reduces uncertainty and builds trust.

How Does Data Integration Improve Decision Making?

When sales, inventory, and supply data connect:

- Demand forecasting improves, reducing both shortages and waste

- Cash flow management becomes predictable with accurate lead times

- Quality tracking identifies patterns connecting origin practices to cup results

- Cost analysis reveals true total costs beyond purchase price

- Risk assessment becomes data-driven rather than intuitive

The goal is creating a digital twin of your physical supply chain that allows simulation and optimization before implementing changes.

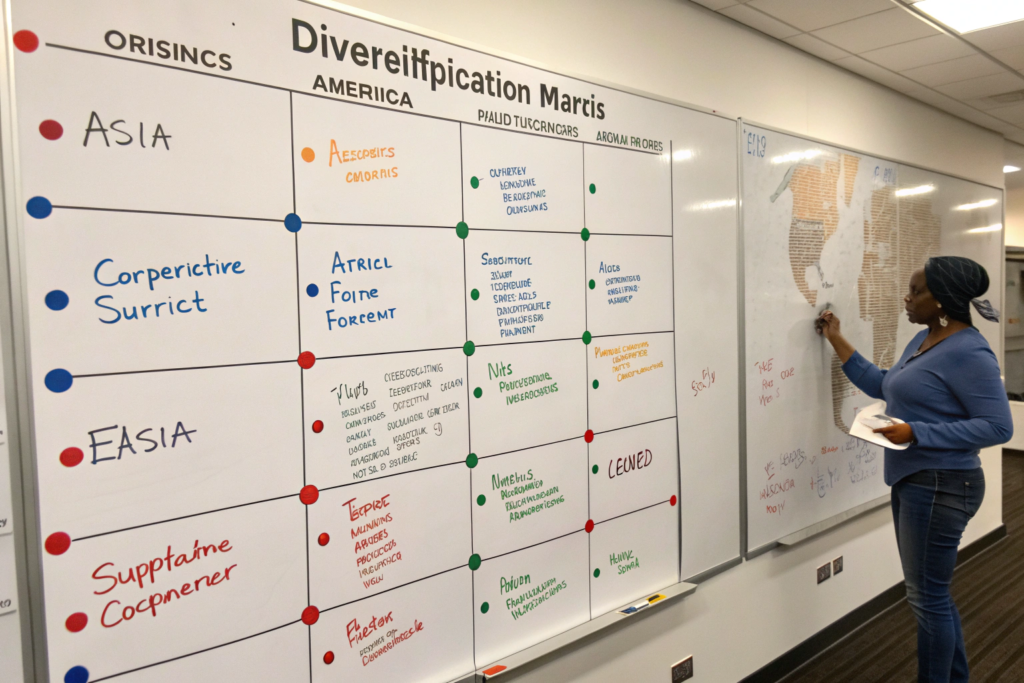

Why is Sourcing Diversification Critical?

Relying on single origins, suppliers, or shipping routes creates vulnerability. Diversification spreads risk while potentially improving quality and cost options.

Strategic diversification balances the efficiency of concentration with the resilience of multiple options, requiring careful planning rather than random addition of suppliers.

How Should You Diversify Effectively?

Consider multiple dimensions:

- Geographic diversification: Source from different continents/climates

- Supplier diversification: Work with both large exporters and direct farm relationships

- Shipping route diversification: Use multiple ports and carriers

- Quality tier diversification: Balance premium lots with consistent commercial grades

- Seasonal diversification: Align purchases with harvest cycles across hemispheres

A diversified portfolio might include Brazilian volume for consistency, Ethiopian specialty for quality differentiation, and our Yunnan supply from BeanofCoffee for geographic and political risk mitigation.

How Do You Manage Multiple Supplier Relationships?

Diversification increases complexity, requiring:

- Standardized specifications across all suppliers

- Centralized quality evaluation for fair comparison

- Relationship management systems to track performance

- Volume allocation strategies based on performance

- Unified contracting with consistent terms where possible

The administrative overhead of multiple suppliers must be balanced against the risk reduction benefits.

How Can Collaborative Partnerships Reduce Friction?

Traditional transactional relationships create information hoarding and adversarial negotiations. Collaborative partnerships share information and align incentives for mutual benefit.

In coffee, true collaboration means farmers, processors, shippers, and roasters working as partners rather than sequential contractors.

What Does a Collaborative Partnership Look Like?

- Shared forecasting: Farmers see your demand projections to plan production

- Transparent costing: All parties understand cost structures and fair margins

- Joint quality improvement: Work together to enhance processing and consistency

- Risk sharing: Collaborate through challenges rather than canceling contracts

- Long-term planning: Multi-year agreements with gradual improvement targets

Our partnerships at BeanofCoffee often involve shared investment in processing equipment or farmer training that improves quality for both parties over years, not just seasons.

How Do You Measure Partnership Value?

Beyond price, evaluate:

- Communication responsiveness during problems

- Flexibility when unexpected issues arise

- Innovation contribution to quality or efficiency

- Transparency about challenges and limitations

- Reliability across multiple seasons and conditions

The strongest partnerships demonstrate consistent performance during both favorable and challenging market conditions.

What Inventory Strategies Balance Cost and Availability?

Coffee inventory represents tied-up capital and quality degradation risk, but insufficient inventory causes stockouts and rushed decisions. Finding the optimal balance is both mathematical and strategic.

Effective inventory management considers coffee's perishability, price volatility, and the lead times inherent in international sourcing.

How Do You Calculate Optimal Inventory Levels?

Consider multiple factors:

- Demand variability: How predictable are your sales patterns?

- Lead times: From order to delivery for each origin

- Quality degradation rate: How quickly does green coffee lose freshness?

- Price trends: Are costs rising or falling?

- Storage costs: Physical space and capital expense

Many roasters use a hybrid approach: maintaining strategic buffer stock of base components while keeping specialty lots in smaller, faster-turning quantities.

What About FIFO and Quality Rotation?

- First-In-First-Out (FIFO): Essential but challenging with multiple lot arrivals

- Quality monitoring: Regular cupping of aged inventory to detect degradation

- Lot segregation: Keeping different harvests separate to preserve traceability

- Condition monitoring: Tracking temperature/humidity in storage areas

- Disaster planning: Having protocols for salvage if storage conditions fail

Even with perfect planning, inventory discipline requires constant attention as conditions change.

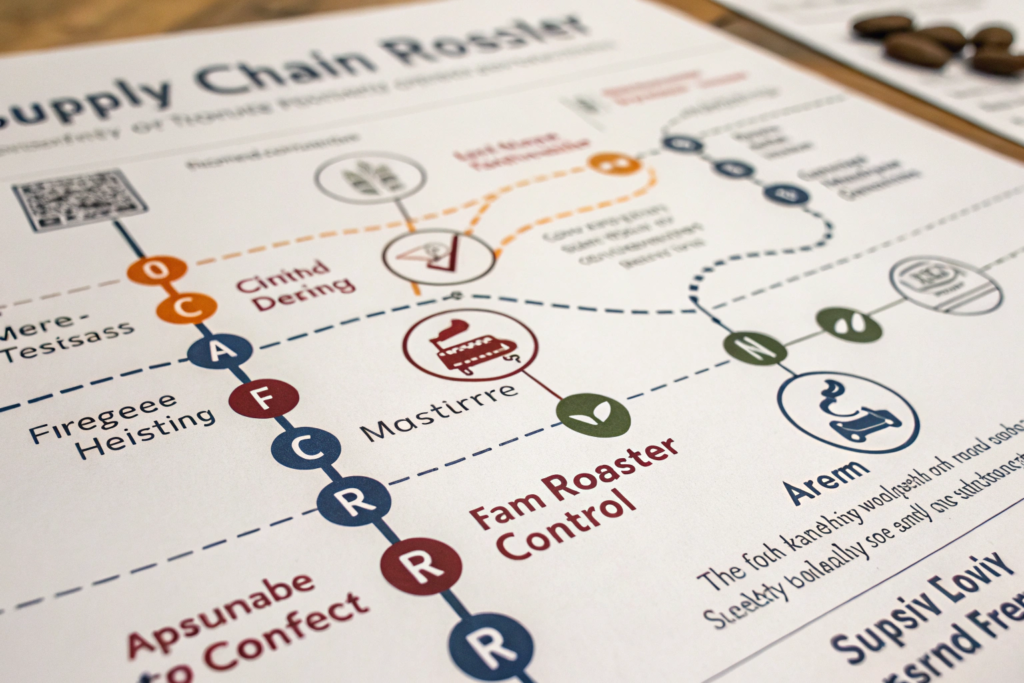

Where Should You Implement Quality Control Checkpoints?

Quality isn't just evaluated at the end—it's preserved through checkpoints that prevent degradation and catch issues early when correction is still possible.

A checkpoint strategy identifies critical control points where failure would be costly or irreversible, then implements verification at those points.

What Are the Critical Control Points?

Typical checkpoints include:

- Pre-shipment at origin: Verify quality matches sample before loading

- Container loading: Ensure proper packaging and handling

- Arrival at destination: Compare against pre-shipment samples

- During storage: Regular monitoring for environmental issues

- Before roasting: Final check against production specifications

At each checkpoint, define acceptable ranges for key metrics (moisture, defect count, etc.) and escalation procedures when standards aren't met.

How Can You Prevent Quality Degradation?

- Packaging standards: Specify GrainPro or equivalent for ocean shipments

- Handling procedures: Train all partners on coffee's fragility

- Environmental controls: Monitor temperature/humidity throughout transit

- Documentation: Ensure complete paperwork follows each lot

- Testing frequency: Regular sampling at vulnerable transition points

The most effective quality systems prevent problems rather than just detecting them.

How Do You Balance Cost, Quality, and Reliability?

Optimization requires balancing competing priorities that often conflict: lower cost versus higher quality, single-source efficiency versus multi-source reliability.

The optimal balance differs by business strategy—a discount brand prioritizes cost, while a specialty brand prioritizes quality, but both need reliability.

What Trade-offs Should You Quantify?

Create decision frameworks that compare:

- Cost of stockouts vs. cost of excess inventory

- Premium for higher quality vs. customer willingness to pay

- Efficiency of single sourcing vs. resilience of multiple sources

- Lower price with longer lead time vs. higher price with faster delivery

- Internal control vs. outsourced convenience

These strategic trade-offs should align with your brand positioning and customer value proposition.

How Can You Improve All Three Simultaneously?

Some initiatives improve multiple dimensions:

- Direct relationships can improve both quality and cost

- Technology investments can improve reliability and reduce costs

- Process standardization can improve quality and reliability

- Volume consolidation can improve cost and reliability

- Partner development can improve quality and reliability

The most powerful optimizations create virtuous cycles where improvements in one area enable improvements in others.

Conclusion

Optimizing your coffee supply chain requires addressing visibility through technology, resilience through diversification, efficiency through partnerships, balance through inventory strategy, and consistency through quality checkpoints. The most successful optimizations recognize that supply chains are interconnected systems where changes in one area affect others.

A truly optimized supply chain isn't just cheaper or faster—it's more predictable, transparent, and adaptable to the inevitable disruptions of global coffee trade. This requires ongoing attention and refinement as markets, climates, and consumer preferences evolve. If you're looking to optimize your supply chain and want to explore how direct partnerships with origin can address multiple optimization goals, contact our export manager, Cathy Cai, at cathy@beanofcoffee.com. We work with partners to create supply chains that balance efficiency, quality, and resilience.