You've just roasted the perfect batch of coffee. The aroma is intoxicating—fruity, floral, complex. But within days in a simple paper bag, those delicate notes fade to a generic "coffee" smell. Your customers receive a shadow of what you created. Packaging isn't just a container; it's a time capsule that must protect hundreds of volatile aromatic compounds from their four enemies: oxygen, moisture, light, and heat.

Packaging coffee to preserve aroma and freshness requires a multi-barrier approach using materials that block oxygen and moisture, incorporate one-way degassing valves, are opaque to light, and maintain seal integrity. The industry standard is a foil-lined bag with a food-grade polyethylene layer, a one-way valve for CO2 release, and a resealable closure. This system creates a controlled environment that dramatically slows staling.

So, what specific materials and technologies actually work, and how do you implement them without breaking the bank? The science of coffee packaging has evolved significantly, moving far beyond simple bags to engineered preservation systems. Let's examine the components that separate packaging that protects from packaging that merely contains.

What Are the Essential Barrier Properties?

Coffee's aromatic compounds are delicate and highly volatile. Effective packaging must create barriers against multiple environmental threats simultaneously.

The primary enemies are oxygen (causes oxidation/staling), moisture (degrades quality and promotes mold), light (accelerates chemical reactions), and odors (coffee absorbs external smells).

Why is Oxygen Barrier the Top Priority?

Oxygen initiates oxidation that:

- Breaks down aromatic compounds (those lovely fruity/floral notes)

- Causes oils to become rancid (creating stale, cardboard flavors)

- Degrades freshness within days if exposed

- Cannot be reversed once it occurs

Foil layers in quality bags provide an oxygen transmission rate (OTR) near zero, typically <0.5 cc/m²/day, compared to paper bags which offer almost no barrier. This absolute oxygen barrier is non-negotiable for freshness beyond a few days.

How Critical is Moisture Protection?

Even small moisture increases:

- Accelerate staling chemical reactions

- Promote mold growth in worst cases

- Degrade flavor clarity and create flat cups

- Change bean texture making grinding inconsistent

Quality bags maintain a water vapor transmission rate (WVTR) below 0.5 g/m²/day, keeping external humidity from affecting the beans. At BeanofCoffee, we use similar barrier packaging for our roasted samples to ensure partners taste the coffee as intended. This moisture management is especially crucial in humid climates.

How Does the Degassing Valve Work?

Freshly roasted coffee releases significant CO2 for days or weeks. Without a valve, this pressure would burst bags or force open seals, allowing oxygen in.

The one-way valve is a brilliant solution: it allows CO2 to escape while preventing oxygen from entering, solving the packaging paradox of needing to release gas while blocking air.

What Happens Without a Proper Valve?

- Bags inflate like balloons, potentially bursting

- Seals break from internal pressure

- Oxygen enters once the seal is compromised

- Freshness plummets as oxidation begins

- Customer receives a degraded product

A functional valve maintains internal pressure equilibrium while preserving the protective atmosphere inside the bag.

How Do You Choose the Right Valve?

Consider:

- Valve size: Should match your bag size and coffee quantity

- Flow rate: Must handle your coffee's degassing volume

- Quality: Cheap valves can fail or allow oxygen ingress

- Placement: Typically on the front upper portion of the bag

- Testing: Valves should be tested for both gas release and oxygen barrier

The valve is a small component with outsized importance—a failed valve negates all other packaging quality.

What Materials and Construction Work Best?

Packaging materials are engineered sandwiches of different layers, each serving a specific protective function while maintaining practicality and aesthetics.

The standard specialty coffee bag consists of 3-4 layers: an outer printable layer for branding, a foil barrier layer, a food-grade inner layer, and sometimes additional structural layers.

What's in a Typical High-Quality Bag?

From outside to inside:

- Outer layer: Polyester or nylon for printing and durability

- Barrier layer: Aluminum foil (typically 7-12 microns) for oxygen/moisture barrier

- Sealant layer: Food-grade polyethylene (PE) or cast polypropylene (CPP) for heat sealing

- Optional layer: Additional polyethylene for strength

This multi-layer construction provides physical protection, complete barriers, and sealability in one package.

How Important is the Seal?

The seal is the weakest point in any barrier system:

- Heat seals must be consistent and complete around all edges

- Seal width should be sufficient (typically 10-15mm)

- Seal temperature must be precisely controlled for the materials used

- Inspection should check for pinholes or weak spots

Even with perfect materials, a failed seal compromises the entire package. Professional packagers use seal testers to verify integrity.

How Does Opacity and UV Protection Matter?

Light, especially UV light, provides energy that accelerates the chemical reactions of staling. Complete opacity is therefore essential, not just a branding choice.

Transparent or translucent bags, while attractive for showing the beans, sacrifice freshness for aesthetics. Any light exposure degrades coffee over time.

Why is Complete Opacity Necessary?

- UV light breaks down aromatic compounds directly

- Visible light provides energy for oxidation reactions

- Even indirect light in retail environments causes damage

- The damage is cumulative and irreversible

Foil layers provide complete light blockage, while metallized films offer partial protection. Plain plastic or paper offers almost none.

What About Branding and Information?

Opacity doesn't mean sacrificing design:

- High-quality printing on the outer layer communicates brand and information

- Windows can be incorporated with UV-blocking filters if showing beans is essential

- Information panels can include roast date, flavor notes, brewing suggestions

- QR codes or NFC tags can link to digital content without compromising barriers

The best packaging balances protective function with communicative design.

What About Resealability and Consumer Experience?

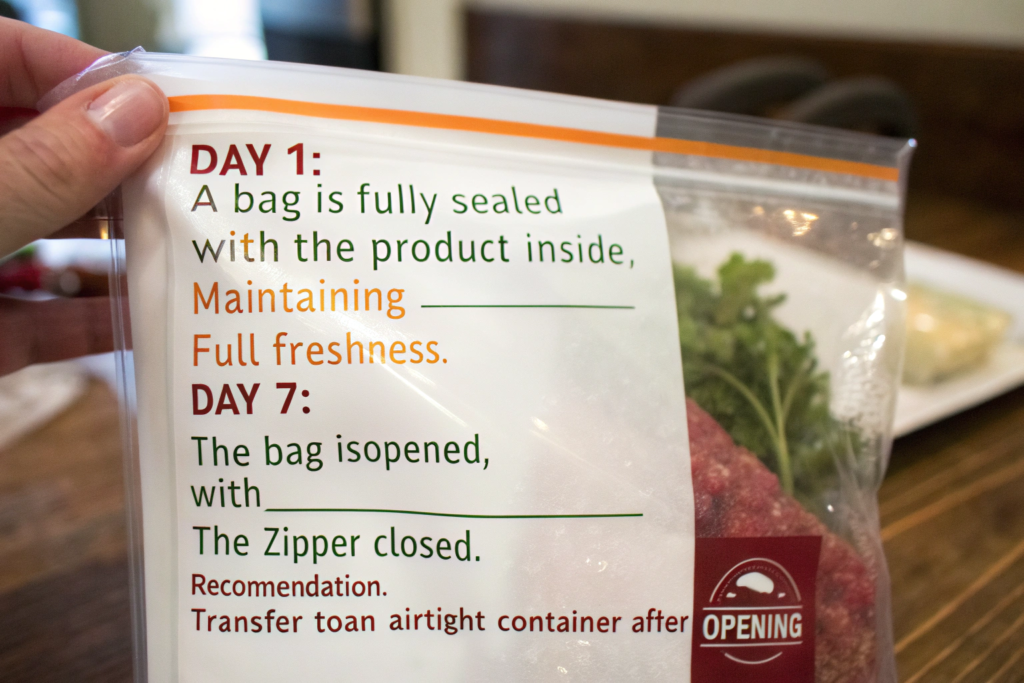

While the initial seal preserves freshness until first opening, resealability maintains what remains after the package is opened.

Zipper closures, while convenient, are not perfect oxygen barriers. Their role is to slow degradation after opening rather than provide complete protection.

How Effective Are Zipper Closures?

Zippers provide:

- Convenience for daily access

- Some protection against moisture and odors

- Limited oxygen barrier (significantly less than the main seal)

- Psychological reminder to close the package

For optimal freshness after opening, many professionals recommend transferring beans to an airtight container and consuming within 1-2 weeks.

What Other Closure Options Exist?

- Tin-tie closures: Simple but effective for rolling the bag closed

- Velcro strips: Reusable but less airtight

- Slide zippers: More secure than press-to-close versions

- No closure: For bags meant to be fully emptied quickly

The choice depends on your customer usage patterns—weekly purchasers need different features than monthly bulk buyers.

How Should You Approach Sustainable Packaging?

The conflict between preservation (requiring plastic/foil barriers) and sustainability (demanding compostable materials) represents one of coffee packaging's biggest challenges.

New materials are emerging that attempt to balance these competing priorities, though they typically involve trade-offs in barrier performance or cost.

What Are the Current Sustainable Options?

- Compostable plastics: PLA-based materials that break down industrially

- Recyclable structures: Mono-material designs that can be recycled

- Paper with bioplastic liners: More sustainable than foil but less protective

- Reusable containers: Encourage customers to refill their own containers

- Reduced material use: Thinner but effective barriers

Each option involves performance compromises that must be clearly communicated to customers.

How Do You Choose Between Freshness and Sustainability?

Consider your:

- Customer values: Do they prioritize environmental impact or optimal freshness?

- Product shelf life: Will coffee be consumed quickly or stored?

- Distribution channel: Direct-to-consumer vs. retail shelf time

- Price point: Sustainable materials often cost 20-100% more

- Brand positioning: How central is sustainability to your identity

Many brands now offer both options—premium foil bags for optimal quality and sustainable options for environmentally conscious customers.

Conclusion

Packaging coffee to preserve aroma and freshness requires a systems approach that addresses multiple threats simultaneously: oxygen barriers (typically foil), moisture protection, light opacity, controlled degassing via valves, and secure seals. While each component matters individually, their integration determines overall effectiveness.

The most successful packaging solutions balance scientific protection with practical considerations like cost, sustainability, and consumer experience. As materials science advances, new options will continue to emerge, but the fundamental principles of barrier protection will remain essential for delivering coffee at its peak. If you're developing packaging for your coffee brand and want to understand how different options affect the beans we supply, contact our export manager, Cathy Cai, at cathy@beanofcoffee.com. We can share our experience with what actually preserves the quality of our coffees during distribution and storage.