You've just secured a container of premium green coffee beans. The quality is perfect, the price is right. But now you face the daunting task of moving these delicate beans across oceans and continents. One mistake in logistics could turn your premium investment into a musty, degraded product worth pennies on the dollar. The journey from farm to port to roaster is where quality is either protected or destroyed.

Shipping coffee beans internationally without damage requires a multi-layered protection strategy focusing on moisture control, physical stabilization, and temperature management. The key elements include using GrainPro or similar hermetic bag liners, proper palletization and container loading, maintaining stable temperatures, and selecting reliable logistics partners with coffee experience. Even one weak link in this chain can compromise your entire shipment.

So, what specific steps separate successful shipments from costly failures? The solution lies in building defensive layers from the bag itself all the way to the container's final destination. Let's examine each critical protection point.

What Packaging Provides the Best Moisture Protection?

Moisture is the arch-nemesis of coffee during transit. Once beans absorb excess humidity, they're vulnerable to mold, mustiness, and irreversible quality loss. The battle begins at the packaging level.

The gold standard for international coffee shipping is multi-layer protection: an inner hermetic bag (like GrainPro) inside a traditional jute or woven poly bag. This creates a barrier against both physical damage and environmental humidity fluctuations.

Why are Hermetic Bags Revolutionary?

GrainPro-style bags are polyethylene liners that create a near-airtight seal around the coffee. They lock the beans at their ideal moisture content (10-12%) and prevent external humidity from penetrating during ocean voyages through humid climates. While jute bags breathe (which can be a disadvantage), hermetic bags provide absolute moisture barrier protection that has revolutionized coffee shipping.

Should You Use Desiccants?

For extra protection in high-humidity routes, food-safe desiccant packets can be added inside the hermetic bags. However, they're not a substitute for proper bags—they're an insurance policy. The key is calculating the right amount based on container volume and transit time. This moisture insurance can be the difference between perfect beans and a moldy disaster when unexpected delays occur.

How Should Coffee Be Loaded into Containers?

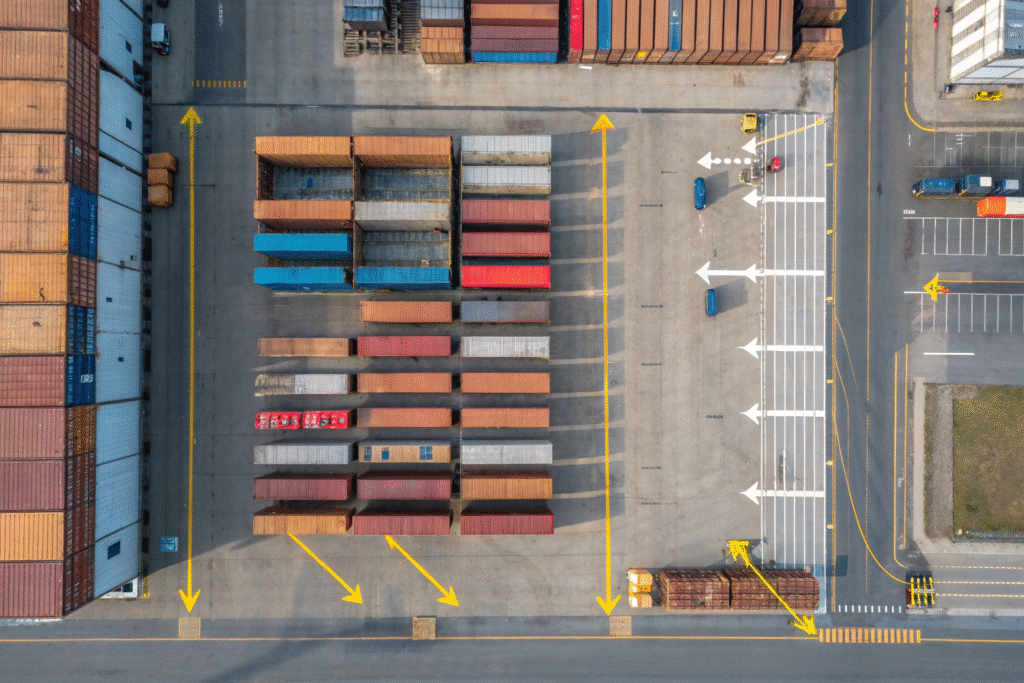

How you arrange bags inside the container matters as much as what those bags are made of. Poor loading creates pressure points, moisture traps, and shifting during transit that can rupture bags and damage beans.

Proper container loading involves strategic palletization, maintaining air circulation, and securing the load to prevent movement during the violent motions of ocean travel.

What is the Optimal Pallet Configuration?

Bags should be stacked in a brick-wall pattern on standardized pallets, never stacked directly against container walls. This creates necessary air channels that allow for air circulation and prevent condensation hotspots where moisture would otherwise accumulate. The pallets themselves should be clean, dry, and free of odors that coffee could absorb.

How Do You Prevent Shifting During Transit?

Even with perfect palletization, ocean voyages can subject cargo to forces that make loads shift. Professional shippers use air bags, load bars, or brace wood to secure pallets firmly in place. This cargo stabilization prevents bags from rubbing against each other or falling—actions that can break beans and create fine particles that accelerate staling.

What Environmental Controls Are Necessary During Transit?

The container itself becomes a microclimate for weeks. Without attention to temperature and ventilation, even perfectly packaged coffee can arrive damaged.

While most coffee ships in standard dry containers, understanding and managing the container environment is crucial for protecting sensitive specialty lots.

How Does Temperature Fluctuation Cause Damage?

Containers sitting in direct sun can reach internal temperatures over 60°C (140°F), which accelerates staling and can cause heat degradation of delicate coffee oils. While temperature-controlled containers are expensive, simple measures like avoiding deck placement and selecting reliable shipping lines that minimize port delays can reduce temperature extremes.

What About Ventilation and Container Selection?

Always specify a "coffee quality" container—one that's clean, odor-free, and hasn't previously carried strong-smelling goods. While coffee doesn't typically require ventilated containers, ensuring there are no lingering odors from previous shipments is non-negotiable. Coffee is like a sponge for foreign odors from chemicals, foods, or previous cargo.

How Can You Choose and Manage Logistics Partners?

Your freight forwarder and shipping line are operational partners, not just vendors. Their expertise and attention to detail directly impact your coffee's condition upon arrival.

Select partners with proven coffee experience, transparent communication practices, and reliable equipment. Then manage them actively throughout the shipment process.

What Questions Should You Ask a Potential Forwarder?

"Can you provide references from other coffee shippers?" "What's your protocol for container inspection before loading?" "How do you track and communicate about delays?" Their answers will reveal their coffee-specific expertise. A forwarder who primarily ships machinery or dry goods may not understand coffee's unique vulnerabilities.

Why is Documentation and Insurance Critical?

Ensure all documentation clearly states "COFFEE BEANS" and includes the roast type (green). This affects how the cargo is handled. More importantly, purchase adequate marine insurance that specifically covers coffee against moisture damage, heating, and contamination. This financial protection is your final backup when physical protection methods fall short.

What Quality Checks Should Happen Before and After Shipping?

Protection begins before loading and continues after unloading. Proactive quality verification at both ends of the journey catches problems early.

Implementing standard quality checks at origin and destination gives you data to identify where in the chain damage occurred—and who's responsible.

What Pre-Shipment Verification is Essential?

Before sealing the container, representative samples should be taken and retained from multiple bags. These should be tested for moisture content and water activity. This creates a quality baseline that protects you if the receiver claims the coffee was already degraded before shipping.

How Should You Handle Receiving and Inspection?

Upon arrival, immediately check the container seal number against your documentation. Before unloading, inspect for obvious damage, odors, or moisture. Take new samples for comparison with your origin samples. If there's a dispute, this documented evidence chain is crucial for insurance claims or supplier discussions.

Conclusion

Shipping coffee internationally without damage is a disciplined process of building protective layers—starting with hermetic packaging, continuing through scientific container loading, and finishing with careful partner management and documentation. There's no single magic solution, only consistent attention to multiple details that collectively ensure quality preservation.

The cost of premium packaging and careful logistics is insignificant compared to the value of delivering pristine coffee that meets your quality standards and protects your brand reputation. At BeanofCoffee, we've built our export process around these principles, ensuring our partners receive coffee in the same condition it leaves our warehouses. For a shipping partner that understands coffee's fragility, contact our export manager, Cathy Cai, at cathy@beanofcoffee.com to discuss how we can ensure your beans arrive perfectly.