You've received a shipment of green coffee beans that look perfect. But during roasting, they develop unevenly with some beans popping early while others barely crack. The problem might not be your roaster—it could be inconsistent moisture content in the beans themselves. Testing moisture isn't just a quality check; it's essential for predictable roasting and avoiding costly defects in your final product.

Testing moisture content in green coffee beans involves using specialized equipment to measure the percentage of water weight in the beans. The most common methods include using a calibrated moisture analyzer (meter), a laboratory oven-dry method, or capacitance-based testers. For accurate results, proper sampling technique and equipment calibration are as important as the testing method itself.

So, how can you ensure your moisture readings are accurate and actionable for your roasting business? The process requires understanding both the science of moisture measurement and the practical steps to get reliable results. Let's explore the methods, best practices, and what the numbers actually mean for your coffee.

What Are the Standard Methods for Moisture Testing?

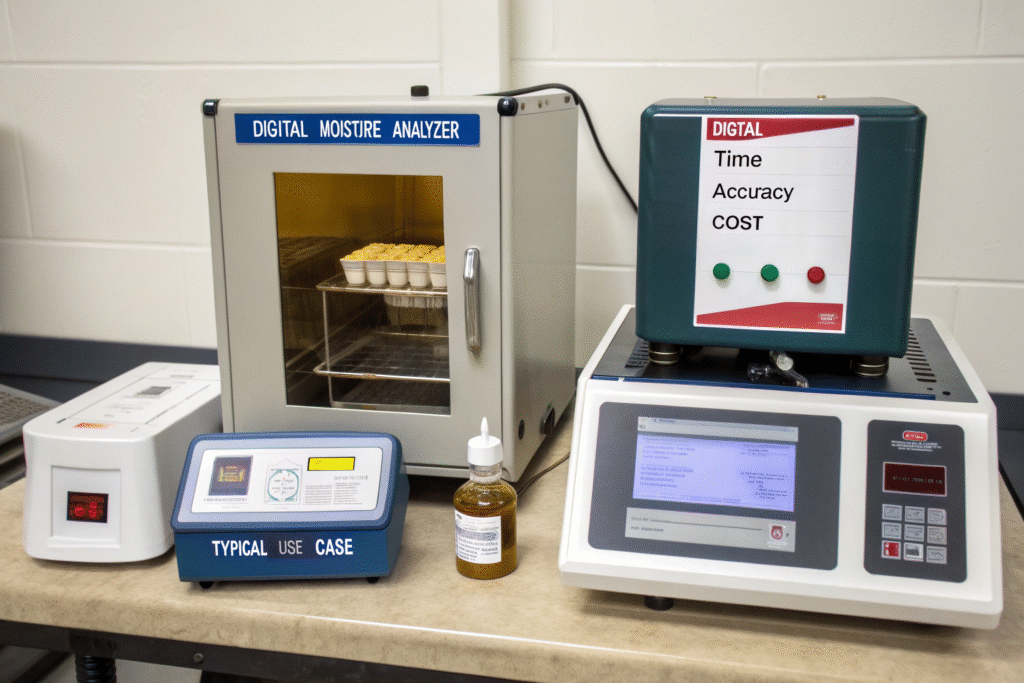

Different testing methods offer varying balances of accuracy, speed, and cost. Choosing the right method depends on your volume, precision requirements, and available resources.

The three primary approaches are instrumental moisture analyzers, traditional oven drying, and capacitance testers. Each has specific applications in the coffee supply chain from farm to roastery.

How Do Digital Moisture Analyzers Work?

These are the industry standard for most commercial operations:

- Principle: Uses halogen or infrared heating to rapidly remove moisture while measuring weight loss

- Process: A small sample (5-10g) is heated while continuously weighed

- Output: Digital display showing moisture percentage

- Time: 5-15 minutes per test

- Accuracy: ±0.1-0.5% when properly calibrated

These devices provide rapid results with good accuracy, making them ideal for quality control at receiving, during storage, and before roasting. At BeanofCoffee, we use calibrated analyzers to ensure every shipment meets our moisture specifications.

What About the Traditional Oven Method?

The classic laboratory method provides high accuracy:

- Principle: Dries samples in a controlled oven, measuring weight before and after

- Process: 100g sample dried at 105°C for 24 hours, then reweighed

- Calculation: Moisture % = [(Initial weight - Final weight) / Initial weight] × 100

- Time: 24+ hours

- Accuracy: Considered the reference standard (±0.1%)

While accurate, this method's time requirement makes it impractical for routine testing but valuable for calibrating faster methods or resolving disputes.

Why is Proper Sampling Critical?

Even the most accurate moisture analyzer gives misleading results if your sample doesn't represent the entire lot. Poor sampling introduces more error than most measurement devices.

Proper sampling means obtaining beans from multiple locations in your shipment or storage container to account for natural variation and potential moisture migration.

How Should You Sample from a Shipment?

For a container or pallet shipment:

- Sample multiple bags (at least 10% of bags for lots under 20 bags)

- Take from different depths within each bag (not just the top)

- Combine samples to create a composite

- Mix thoroughly before taking your test portion

- Test immediately or store in airtight container

This representative sampling ensures you're measuring the true average moisture, not just a lucky or unlucky spot.

What About Sampling During Storage?

Moisture can migrate in storage, creating "hot spots":

- Sample from different heights in storage bins or silos

- Check areas near walls where condensation might occur

- Test after significant temperature changes

- Monitor over time to detect gradual changes

Regular monitoring protocols help you catch issues before they affect your entire inventory.

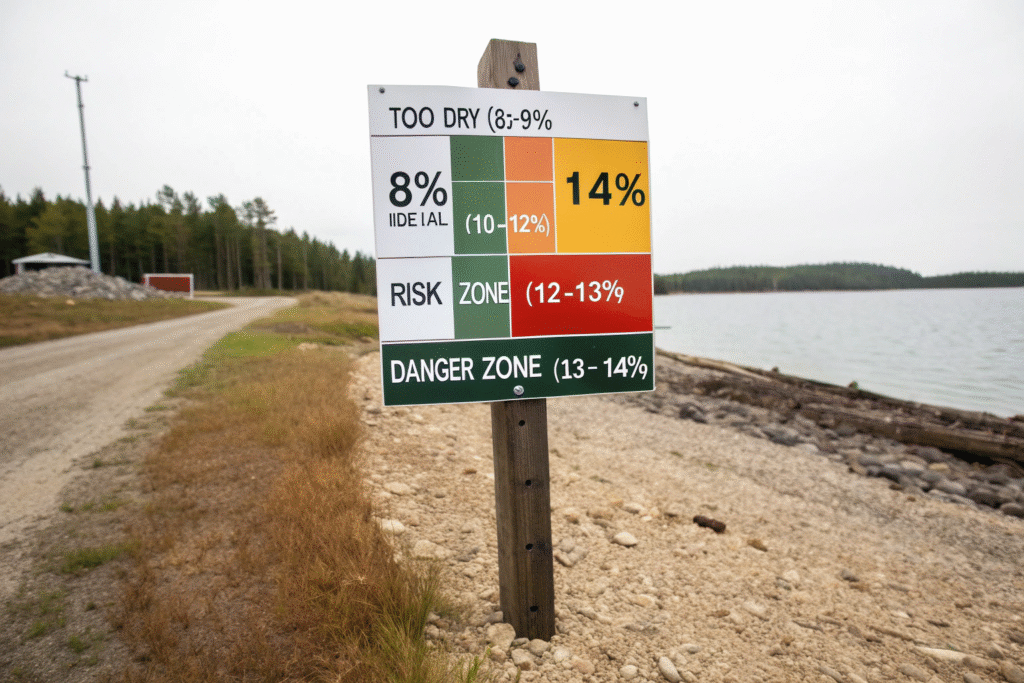

What Is the Ideal Moisture Range for Green Coffee?

Moisture content affects everything from shelf life to roasting behavior. Knowing the target range helps you interpret your test results and take appropriate action.

The Specialty Coffee Association recommends 10-12% moisture for green coffee. Within this range, different percentages have different implications for storage and roasting.

Why is 10-12% Considered Ideal?

This range balances competing needs:

- Below 10%: Beans become brittle, increasing breakage during handling

- Above 12%: Risk of mold growth and quality degradation increases

- 10-11%: Optimal for long-term storage (6-12 months)

- 11-12%: Good for shorter-term storage with careful monitoring

At BeanofCoffee, we target 10.5-11.5% at shipment to provide a safety margin for potential moisture uptake during transit.

How Does Moisture Affect Roasting?

Moisture content directly impacts roast dynamics:

- Higher moisture requires more energy to drive off water before roasting begins

- Lower moisture beans roast faster and may need lower charge temperatures

- Inconsistent moisture causes uneven roasting within the same batch

- Extreme low moisture (<9%) can lead to baked flavors rather than proper development

Understanding these roasting implications helps you adjust your profiles based on measured moisture content.

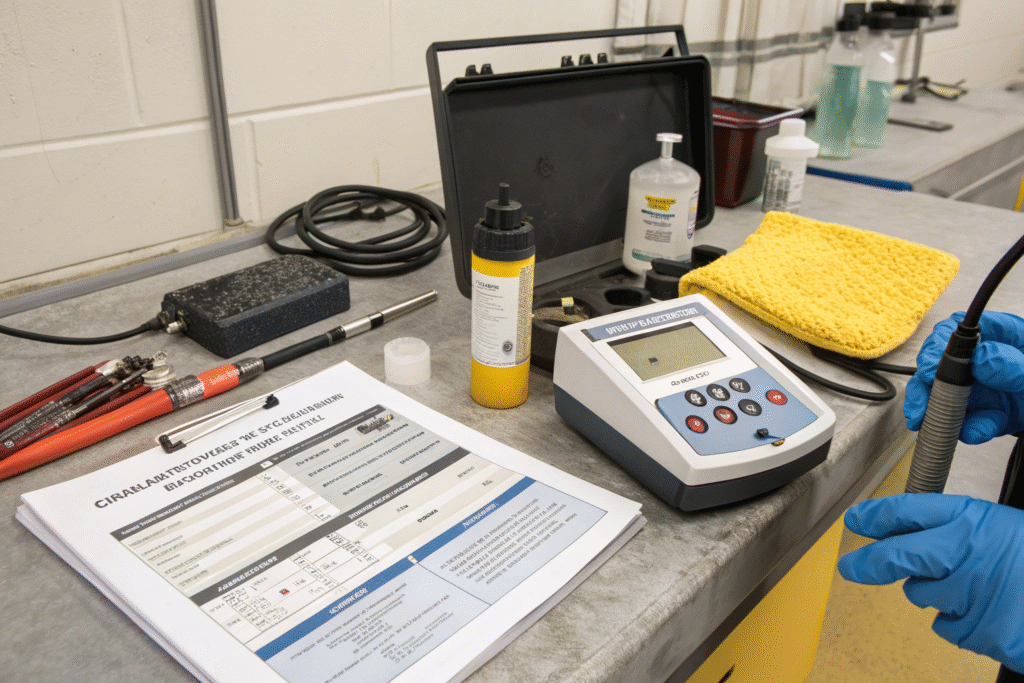

How Can You Ensure Measurement Accuracy?

Moisture testing seems straightforward, but numerous factors can compromise accuracy. Proper technique and equipment maintenance are essential for reliable results.

Accuracy depends on equipment calibration, environmental conditions, sample preparation, and operator technique. Ignoring any of these factors can lead to costly errors.

Why is Calibration So Important?

Moisture analyzers drift over time and require:

- Regular calibration using manufacturer-provided standards

- Routine verification with samples of known moisture

- Environmental compensation for temperature and humidity

- Proper maintenance of heating elements and sensors

A meter that's 1% off can mean the difference between safe storage and mold development. This measurement integrity justifies regular calibration schedules.

How Do Environmental Factors Affect Readings?

- Ambient humidity can affect samples before/during testing

- Temperature variations change equipment performance

- Sample temperature if beans are significantly warmer/cooler than ambient

- Altitude differences affect boiling points and drying rates

Controlling these environmental variables improves consistency between tests and locations.

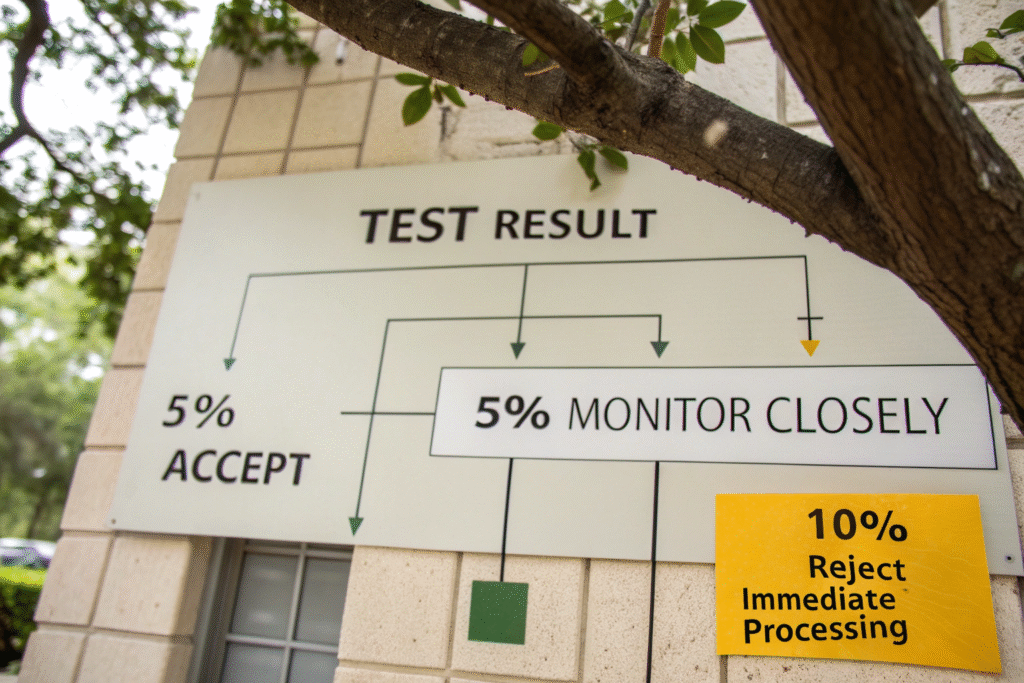

What Actions Should You Take Based on Results?

Testing moisture is pointless unless you act on the results. Different readings require different responses in storage management, roasting adjustments, or even shipment acceptance.

Your response should consider both the absolute moisture percentage and the consistency across samples from the same lot.

What If Moisture is Outside the Ideal Range?

- Below 9.5%: Consider shorter storage times, gentler handling

- Above 12.5%: Implement enhanced monitoring for mold

- Above 13%: Consider rejection or immediate processing

- Extreme cases (>14% or <8%): Likely indicates serious quality issues

These action thresholds help you make objective decisions rather than guessing based on intuition.

How Do You Handle Inconsistent Moisture Within a Lot?

Variation can be more problematic than uniformly high or low moisture:

- Segregate portions with different moisture levels if possible

- Blend carefully during roasting to average out differences

- Adjust roasting to accommodate the wettest beans

- Investigate causes (poor storage, mixing of lots, etc.)

Addressing moisture heterogeneity often requires both immediate action and process improvements to prevent recurrence.

Conclusion

Testing moisture content in green coffee is a critical quality control measure that directly impacts storage stability, roasting consistency, and final cup quality. While the testing process requires proper equipment and technique, the investment pays dividends through more predictable roasting and reduced risk of quality defects.

The most effective approach combines accurate measurement with systematic sampling, regular calibration, and clear action protocols based on results. Whether you're a small roaster testing incoming shipments or a large importer monitoring warehouse conditions, reliable moisture data helps you protect your coffee investment and deliver consistent quality to your customers. If you're concerned about moisture management in your supply chain, contact our quality team at cathy@beanofcoffee.com—we routinely test and document moisture levels for all our shipments and can help you establish effective testing protocols.