You're inspecting a sample of green coffee beans. The price seems right, but you notice a few black beans mixed in with the green. Some are broken. Others look faded. Are these minor issues, or do they signal a deeper quality problem that will ruin your roast and disappoint your customers? Knowing how to spot and evaluate defects is your first line of defense in purchasing.

Standard defects in green coffee beans are imperfections that negatively impact the final cup's flavor, aroma, and cleanliness. They are categorized into primary defects (which are severe and often cause a single bean to ruin a cup) and secondary defects (which are less severe but in high numbers degrade overall quality). Recognizing these defects allows you to assess true value and avoid costly mistakes.

So, what specific flaws should you be hunting for, and what do they actually taste like in the brew? Let's break down the defect catalog and connect visual clues to their disastrous flavors.

What Are the Primary Defects That Ruin a Cup?

Primary defects are the "zero-tolerance" flaws. Just one of these beans in your grinder can introduce harsh, off-flavors that are impossible to ignore. They are the main criteria used in formal grading systems, like the one from the Specialty Coffee Association (SCA).

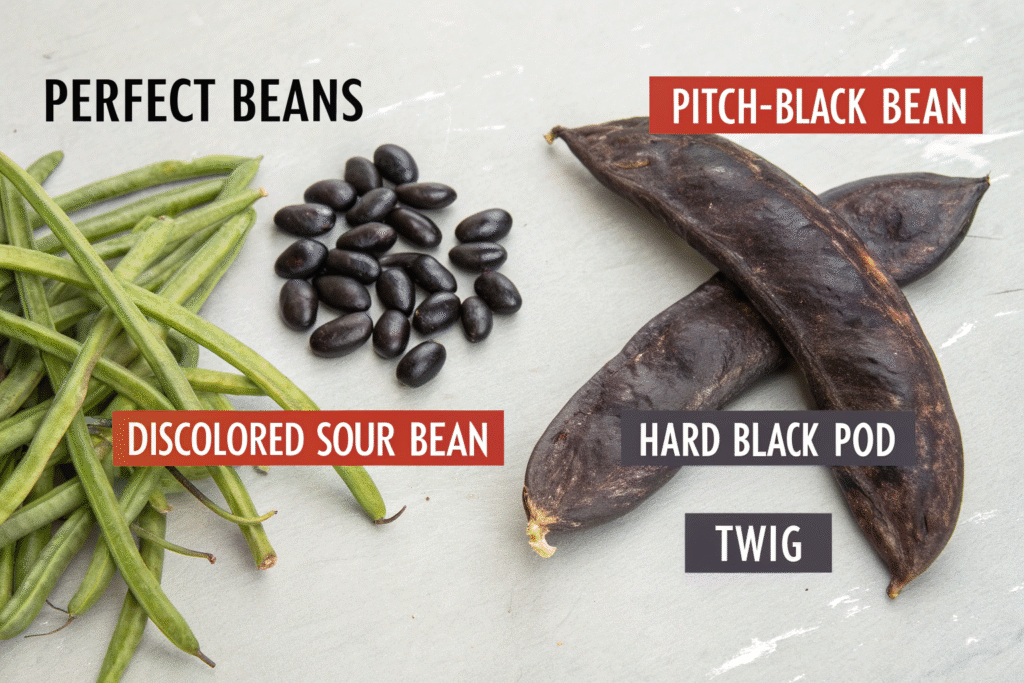

Primary defects include full black beans, full sour beans, dried coffee cherries ("pods"), foreign matter (stones, sticks), and severe insect damage. Each of these is a major fault that can single-handedly disqualify a coffee from the specialty grade.

How Does a Single Black Bean Destroy Flavor?

A black bean is essentially rotten. It's the result of over-fermentation or a dead seed inside the cherry. When roasted and brewed, it tastes intensely bitter, medicinal, and ashy. Honestly, it's the flavor of something that has gone bad. One black bean in a 350g batch is enough to taint the entire pot of coffee with a foul, rubbery taste. This is why visual quality control is non-negotiable.

What is the Impact of a Sour Bean?

A sour bean is different from the bright acidity we desire. It's caused by fermentation starting while the seed is still inside an overripe or damaged cherry. It roasts unevenly and tastes intensely sour, vinegary, or fermented. You know that "fermented fruit" smell that's good in a wine but terrible in your morning cup? That's a sour bean. Identifying this requires a keen eye for subtle color changes and a strict sorting process.

What Are the Secondary Defects and Their Cumulative Effect?

Secondary defects are the "death by a thousand cuts." Individually, they might not ruin a cup, but a high concentration of them leads to a flat, weak, or generally unpleasant coffee. They indicate poor processing, handling, or storage.

Secondary defects include broken/chipped beans, partial black or sour beans, faded/quaker beans, hulls/husks, and slight insect damage. While less severe, they are a key indicator of the overall care taken post-harvest.

Why are Faded Beans ("Quakers") a Problem?

Quakers are beans that never properly matured. They are pale, chalky, and often shriveled. Because they never developed sugars, they don't caramelize during roasting. Instead, they taste like raw peanuts or cereal and leave a papery, dry sensation in your mouth. They are flavor vacuums in a sea of complexity. Spotting them in green form takes practice but is crucial for ensuring roast consistency.

How Do Hulls and Broken Beans Affect Quality?

Hulls (the parchment skin) and broken beans are processing defects. Hulls can burn during roasting, adding a harsh, bitter note. Broken beans have a much larger surface area, causing them to roast faster and darker than whole beans. This leads to uneven extraction—you'll simultaneously get sour under-extracted notes from the whole beans and bitter over-extracted notes from the broken pieces. This inconsistency is a hallmark of poor post-harvest handling.

How is Green Coffee Graded Based on Defects?

Defects aren't just identified; they're counted and scored. This systematic approach is what separates an emotional opinion from a professional quality assessment. The SCA grading protocol is the global standard for this.

Coffee is graded by sampling 350g of green beans. Defects are counted and assigned a penalty points value. Primary defects are worth 1 full point each. Secondary defects are smaller fractions. The total defect score determines if the coffee qualifies as "Specialty Grade" (must have 0 primary defects and fewer than 5 secondary defects).

What is the Step-by-Step Grading Process?

A certified Q Grader will take the 350g sample and sort it meticulously. They will physically count each fault. For example, one full black bean = 1 defect point. Five broken beans = 1 defect point (as five secondaries equal one full defect). The process is mathematical and rigorous. This formal defect grading is how we ensure every lot we export from BeanofCoffee meets the specialty standard.

Can a Coffee Have Defects and Still Be Good?

For commercial-grade coffee, yes. But for specialty coffee, the tolerance is extremely low. The SCA's "zero primary defects" rule is strict for a reason: the presence of even one indicates a fundamental breakdown in quality control that likely affected more than just that single bean. It's a proxy for the overall care level. This is the core of specialty coffee definition.

How Can You Identify and Manage Defects Before Roasting?

You don't need to be a certified Q Grader to protect your business. Implementing simple, proactive checks at your roastery can save you from public failures and financial loss.

Practical steps include always inspecting pre-shipment samples, using simple tools like a sorting tray and a bright light, and establishing a clear defect tolerance in your purchasing agreements with suppliers.

What is the Simple "Tray Test"?

Before you buy a bag, let alone a container, take a 100-200g sample. Spread it thinly on a black or white sorting tray under a bright, cool light. Slowly and methodically scan the beans. Look for the stark contrast of black beans, the slight discoloration of sour beans, and the pale, sad look of quakers. This 5-minute visual inspection can reveal 90% of potential problems. It's the most basic form of supplier verification.

Why is a Clear Contract Crucial?

Your purchase order should specify the maximum allowable defect count, often referencing the SCA standard. This holds your supplier accountable and provides a clear basis for rejection or a price adjustment if the delivered goods don't match the sample. A reliable supplier, like us at BeanofCoffee, will provide this transparency upfront because we have the farming and processing control to back it up. This is what builds long-term supplier trust.

Conclusion

Understanding green coffee defects is fundamental to making intelligent purchasing decisions and producing a superior final product. Primary defects like black and sour beans are cup-wreckers that must be avoided at all costs, while a high count of secondary defects like quakers and broken beans points to careless processing that will flatten your coffee's potential.

Your ability to identify these flaws empowers you to buy with confidence, negotiate from a position of knowledge, and build a brand known for its consistent quality. Never underestimate the power of the raw ingredient. For roasters who will not compromise on quality, sourcing from suppliers with integrated farm control is the ultimate safeguard. We invite you to inspect our samples and see the difference rigorous defect sorting makes. Contact our export manager, Cathy Cai, at cathy@beanofcoffee.com to request a sample lot of our meticulously graded Yunnan Arabica.