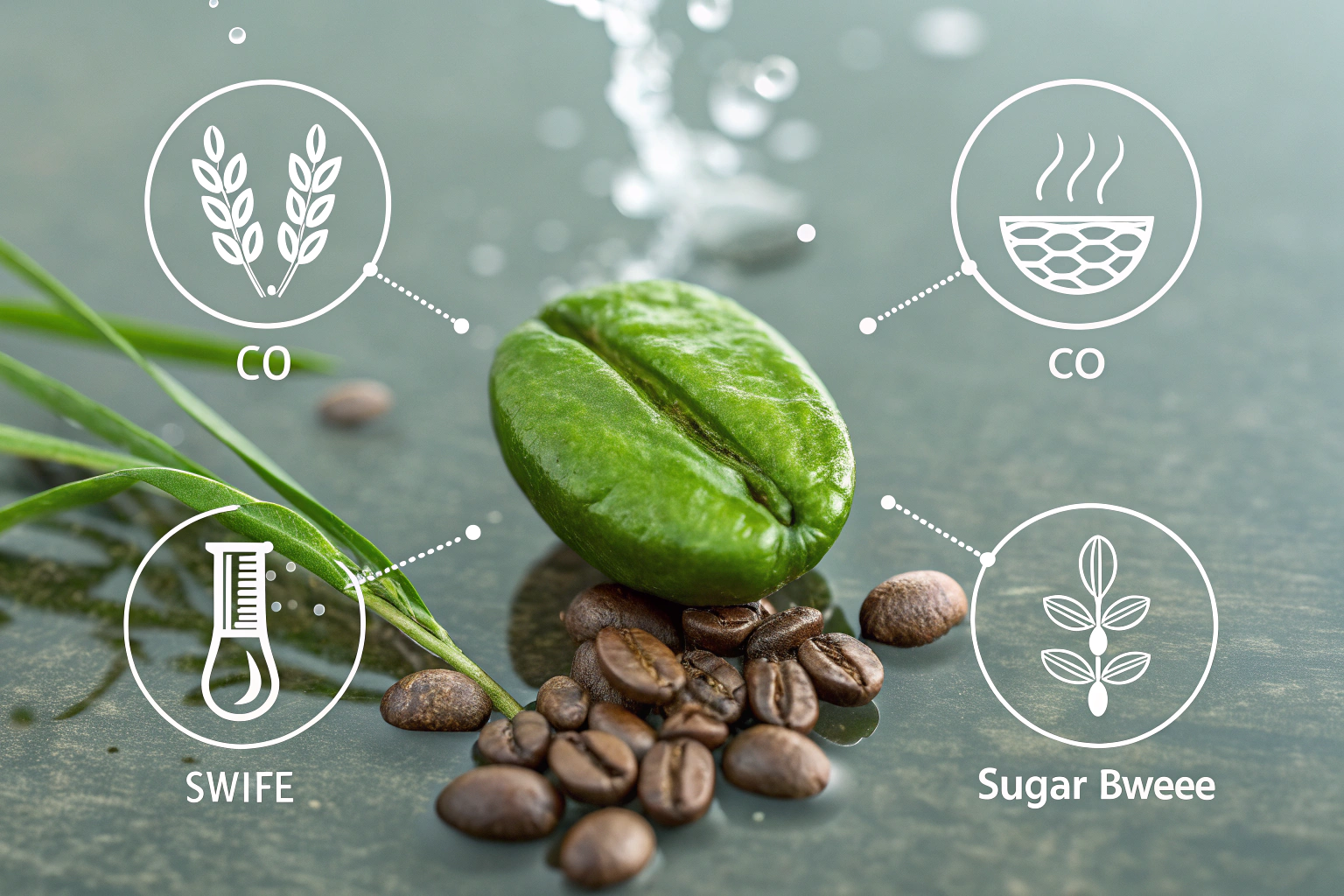

You've probably noticed that decaf has a bad reputation. It's often seen as a flavorless, chemical-laden afterthought. You might be hesitant to even offer it, worried that it will be a subpar product that reflects poorly on your brand. You hear about different decaffeination methods—Swiss Water, Sugarcane, CO2—and it's confusing. Which one is "good"? Which one is "natural"? And which one actually produces a decaf coffee that tastes like... well, coffee?

Honestly, the main difference between decaf methods lies in the "solvent" used to remove the caffeine: some use only water (Swiss Water), some use a natural solvent derived from sugarcane (Sugarcane E.A.), some use carbon dioxide (CO2), and others use synthetic chemical solvents (Methylene Chloride/Ethyl Acetate). The choice of method directly impacts the final flavor profile and the "natural" marketing story of the coffee.

I've always believed that if you're going to do something, you do it right. That applies to decaf, too. When we select beans for decaffeination, we choose beans with a robust enough character to withstand the process. The goal is to remove the caffeine, not the soul of the coffee. Understanding these methods will empower you to choose a decaf you can be proud of, one that honors the bean's origin, whether it's from our farms in Yunnan or anywhere else in the world.

What Is the Swiss Water® Process?

The Swiss Water® Process is probably the most famous and well-marketed of all the "natural" decaffeination methods. Its brand is built entirely on the promise of being 100% chemical-free, using only water to remove the caffeine. For buyers looking for a clean label and a strong marketing story, this method is often the top choice.

The Swiss Water® Process is a unique, non-solvent method that uses a proprietary "Green Coffee Extract" (GCE) to remove caffeine. This GCE is essentially water saturated with all the water-soluble solids found in coffee, except for caffeine. When caffeinated beans are submerged in this extract, the caffeine migrates from the beans into the extract, while the beans retain their original flavor compounds.

It's a clever use of osmosis and solubility. The GCE is too "full" of coffee solids to strip the flavor from the beans; the only thing it has room to absorb is the caffeine. The now-caffeinated GCE is then passed through carbon filters that capture the caffeine molecules, regenerating it for the next batch. It's a gentle, albeit slow and expensive, process.

Is it truly chemical-free?

Yes. The Swiss Water® Process is certified organic and uses no added chemical solvents at any stage. The only elements involved are green coffee, water, and carbon filters. This makes it a powerful selling point for health-conscious consumers and a requirement for any coffee that is to be sold as "Certified Organic Decaf."

What does it taste like?

Because the process is so gentle, it tends to preserve a good amount of the coffee's original character and body. It can sometimes result in a slightly milder or softer flavor profile compared to the original caffeinated bean, but it is widely regarded as one of the best methods for maintaining high quality and a clean taste. It's a reliable choice for preserving the quality of a premium bean from a supplier like Shanghai Fumao.

What Is the Sugarcane E.A. Process?

This method, often called "Natural Decaf" or "Sugarcane Decaf," has become increasingly popular, especially for coffees from Colombia. It uses a solvent, but a naturally derived one, which gives it a unique position in the market. It's often praised for its ability to preserve sweetness and fruit-forward flavors.

The Sugarcane E.A. (Ethyl Acetate) process is a decaffeination method where coffee beans are first steamed to open their pores and then submerged in a solvent of ethyl acetate. This E.A. is naturally occurring and is often sourced from the fermentation of local sugarcane, hence the name. The E.A. bonds with the caffeine molecules and is then washed off, removing the caffeine with it.

After the caffeine removal, the beans are steamed again to remove any residual E.A. The appeal of this method is its "natural" story. Ethyl acetate is a compound found in many fruits, like bananas and, of course, sugarcane. While it can also be produced synthetically, the process for coffee almost always emphasizes the natural, sugarcane-derived source.

Is it safe?

Absolutely. Ethyl acetate is a common food additive and is considered very safe. The amount of residual E.A. left on the bean after processing is minuscule, far below safety thresholds, and it is completely vaporized during the roasting process. The FDA considers it a safe decaffeination agent.

How does it affect the flavor?

This is where the Sugarcane process shines for many. Proponents of this method find that it does an excellent job of preserving the coffee's original sweetness and acidity. Some even say that the process can impart a subtle, pleasant, fruity or rum-like note to the beans, enhancing their flavor profile. This makes it a fantastic choice for bright, fruity coffees where preserving those delicate top notes is the primary goal.

What Is the CO2 Method?

The Carbon Dioxide (CO2) method is the high-tech, precision approach to decaffeination. It uses CO2 in a special "supercritical" state—somewhere between a liquid and a gas—to act as a highly selective solvent for caffeine. It's a sophisticated and expensive process, often used for large batches of commercial coffee.

In the CO2 method, water-soaked green coffee beans are placed in a high-pressure chamber which is then filled with liquid CO2. By raising the pressure and temperature, the CO2 reaches a "supercritical" state where it has the properties of both a gas and a liquid. This allows it to penetrate deep into the coffee beans and dissolve the caffeine molecules, while leaving the larger flavor molecules behind.

The caffeine-laden CO2 is then transferred to another chamber where the pressure is released, causing the CO2 to return to a gaseous state and leave the caffeine behind as a powder. The now-clean CO2 can be re-pressurized and used again, making it an efficient and environmentally friendly process.

What are the advantages of the CO2 method?

The biggest advantage is its extreme selectivity. Supercritical CO2 is an excellent solvent for caffeine but a poor one for the carbohydrates and proteins that create flavor and aroma. This means it can remove the caffeine with very minimal impact on the coffee's original taste profile. It is known for producing a very clean cup that is often difficult to distinguish from the original caffeinated version.

Why isn't it used for all coffees?

The primary reason is cost. The equipment required to create and maintain the high-pressure environment is incredibly expensive. This means the process is only economical for very large quantities of coffee. It's less common for single-origin, specialty micro-lots and more common for large, consistent blends from major brands. It's a fantastic method, but often reserved for the commercial coffee market.

What Are Direct Solvent Methods?

This category covers the oldest and most common methods of decaffeination. They are often referred to as "traditional" or "European Process." While they have a more "chemical" reputation, they are highly effective and, when done well, can produce excellent-tasting decaf coffee.

Direct solvent methods involve steaming the green coffee beans and then repeatedly rinsing them with a chemical solvent, either Methylene Chloride or Ethyl Acetate (often synthetically produced in this case), which bonds with and removes the caffeine. The beans are then steamed and washed again to remove any residual solvent before being dried.

These methods are very efficient and cost-effective, which is why they are so widely used. However, the use of synthetic chemicals, particularly Methylene Chloride, has been a point of concern for some consumers, even though the process is proven to be safe.

Is Methylene Chloride safe?

Methylene Chloride is a solvent that has been used for decaffeination for decades. The FDA has very strict regulations on its use, permitting a maximum residual amount of only 10 parts per million (ppm). In reality, the levels found in decaf coffee are typically non-detectable or far below this limit, as the compound is highly volatile and vaporizes at a much lower temperature than coffee is roasted at. While its safety is scientifically established, the "chemical" perception remains a marketing challenge.

How do they compare in taste?

Many coffee professionals argue that the Methylene Chloride method is actually superior for flavor preservation. Because the solvent is so specific to caffeine, it can be very effective at removing it while leaving the flavor compounds almost entirely intact. It is particularly good at preserving the coffee's body and mouthfeel. When you taste a surprisingly full-bodied and flavorful decaf at a great price, there's a good chance it was decaffeinated using this highly efficient method.

Conclusion

The world of decaf is far more nuanced and interesting than its reputation suggests. The method used to remove the caffeine has a profound impact on the final cup, the cost, and the story you can tell your customers. There is no single "best" method—only the best method for a specific coffee and a specific market. The water-only purity of Swiss Water®, the natural fruitiness of Sugarcane E.A., the high-tech precision of CO2, and the flavor-preserving efficiency of solvent methods all have their place. As a buyer, understanding these differences allows you to make an informed choice and source a decaf that you can be truly proud to serve.

We believe that a great decaf starts with a great bean. We can work with you and our decaffeination partners to select the best beans from our farms and the best process to match your quality and marketing needs. If you're ready to elevate your decaf offering, let's start a conversation. Contact our coffee specialist at cathy@beanofcoffee.com to explore the possibilities.