If you've ever tasted a coffee described as "earthy, funky, and full-bodied" from Indonesia, and another labeled "sweet, syrupy, and clean" from Costa Rica, you've likely experienced the polar ends of the coffee processing spectrum. The terms "Wet Hulled" (Giling Basah) and "Honey Process" are often mentioned in the same breath as "semi-washed" methods, but that's where the similarity ends. They produce dramatically different flavor profiles because their core objectives and execution are worlds apart.

Understanding this difference is crucial for any roaster or buyer. Your choice here directly dictates the flavor palette you're buying into, the pricing, and even the roasting strategy. At BeanofCoffee, while we specialize in the clean, fully-washed profiles of Yunnan Arabica, we know our clients need to navigate the entire market. Let's demystify these two methods by starting with their fundamental goal: Wet Hulling is about speed and pragmatism in humid climates, while Honey Processing is about intentional sweetness and experimentation in controlled environments.

So, what actually happens to the bean? Wet Hulling aggressively removes the parchment while the bean is still spongy and high in moisture. Honey Process deliberately leaves a layer of sticky fruit mucilage on the bean as it dries. This single difference in timing and technique cascades into everything from flavor to market price.

What Happens During the Wet Hulling (Giling Basah) Process?

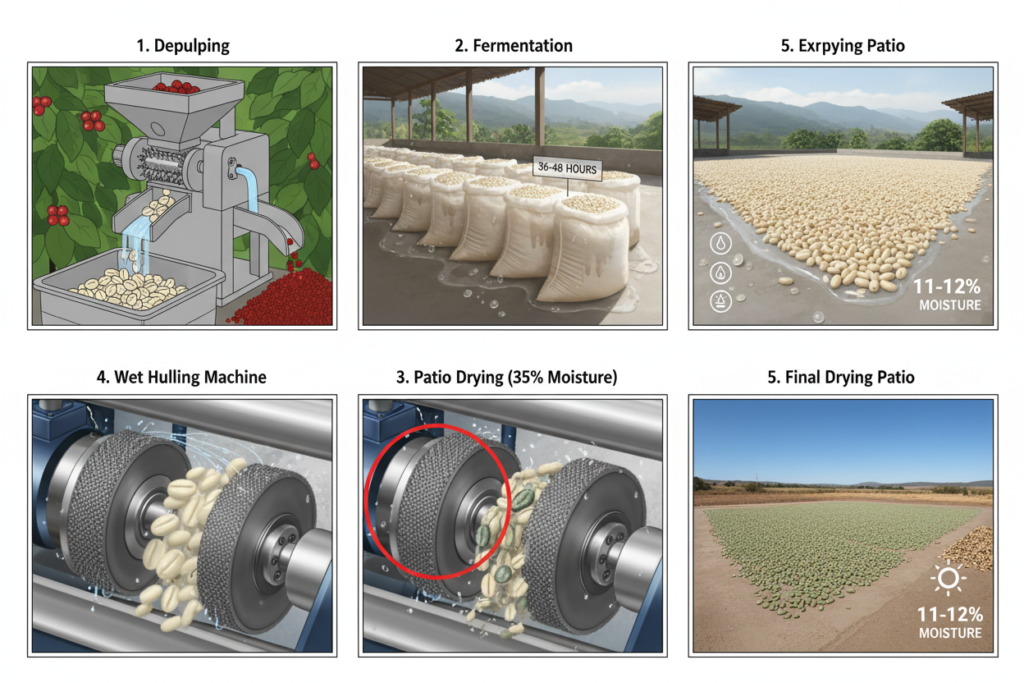

Wet Hulling, known locally in Indonesia as Giling Basah, is a pragmatic response to a specific climate. In regions with high humidity and frequent rainfall (like Sumatra), sun-drying coffee to the standard 10-12% moisture content can take weeks and risks mold. Farmers needed a faster method. Here's the step-by-step breakdown:

- Depulping: The skin and most of the fruit pulp are mechanically removed, just like in the washed process.

- Brief Fermentation & Washing: The beans, still coated in mucilage inside their parchment, may ferment in water for a short time (often just a few hours) before being washed clean.

- Partial Sun-Drying: This is the key. The beans are dried on patios until they reach a much higher moisture content than elsewhere—typically 30-35%. At this point, the bean inside the parchment is still soft and spongy.

- Wet Hulling (Giling Basah): The beans are fed into a hulling machine while still wet and soft. The machine aggressively removes the parchment. The exposed, soft, bluish-green bean (now called green bean) is extremely vulnerable.

- Final Drying: The naked, soft beans are then dried again on patios down to the stable 10-12% moisture for export. This final drying stage happens without the protective parchment layer.

This aggressive removal of the parchment at high moisture is what defines the method. It's fast, efficient for the climate, but it leaves the bean exposed during a critical phase, which profoundly impacts the cup.

Why Does Wet Hulling Create Such Unique "Earthy" Flavors?

The flavors—often described as earthy, woody, herbal, spicy, or funky—are a direct result of the bean's exposure. When the soft, high-moisture bean is stripped of its protective parchment, two things happen:

- Microbial Interaction: The bean is exposed to air and environmental microbes during the final drying. This can introduce the complex, sometimes wild, fermentation notes characteristic of Sumatran coffees.

- Physical Stress: The mechanical hulling of a soft bean can cause micro-fissures and stress, which some believe contributes to the heavier body and lower acidity.

It's a high-risk, high-reward method. Poorly executed, it can lead to harsh, musty defects. Well-executed, it creates a cup of incredible depth, syrupy body, and unique character that is unmistakable. This profile is a cornerstone of many classic espresso blends for its ability to add body and complexity.

Where is Wet Hulling Primarily Used and Why?

Wet Hulling is almost exclusively associated with Indonesia, particularly Sumatra, Sulawesi, and Papua. The climate is the dictator here. The high humidity and unpredictable rain make the slow, full drying required for other methods impractical. Wet Hulling gets the coffee to a stable, exportable condition in a fraction of the time, reducing the risk of spoilage for smallholder farmers. It is a brilliant adaptation to local conditions, not a style chosen purely for flavor experimentation.

What Defines the Honey Process?

Honey Process is a family of methods that deliberately keep some of the fruit's mucilage on the bean during drying. The name comes from the sticky, honey-like feel of the mucilage, not the taste. It sits on the spectrum between the clean, acid-forward Washed process (all mucilage removed) and the fruit-forward Natural process (dried inside the entire fruit). The amount of mucilage left on determines the "color" (White, Yellow, Red, Black Honey), which indicates the level of sweetness and fruitiness.

Here’s the standard workflow:

- Skin Removal & Depulping: The outer skin of the cherry is removed by a depulping machine. The machine is adjusted to leave a specific, controlled amount of mucilage on the bean.

- Mucilage Assessment: The beans, now sticky and coated, are immediately moved to drying beds. No washing or fermentation in water occurs at this stage.

- Protected Drying: This is the critical phase. The sticky beans are dried slowly on raised beds, often under shaded canopies or with frequent turning to control fermentation. The goal is to dry the bean with the sugary mucilage intact, allowing the sugars to slowly seep into the seed.

- Milling: Once fully dried to 10-12% moisture, the now-hard, shriveled mucilage and the parchment are milled off together in one step, revealing the green bean.

The entire process is about control, patience, and intention. The producer is crafting a specific sweetness profile.

How Do Different "Colors" of Honey Affect the Flavor?

The "color" denotes how the drying was managed, primarily through agitation and coverage:

- White Honey: Most mucilage removed (like a light wash). Dried quickly. Tastes closest to a Washed coffee—clean, bright, acidic.

- Yellow/Red Honey: A moderate amount of mucilage. Dried with careful turning. Imparts noticeable sweetness, body, and stone-fruit or caramel notes, with balanced acidity.

- Black Honey: Almost all mucilage left on. Dried very slowly with minimal turning, often covered. This is a risky, labor-intensive method that produces intense sweetness, heavy body, and deep fruity or fermented notes, lower in acidity.

Each step toward "black" increases sweetness, body, and perceived risk/reward. It’s a tool for producers, especially in Costa Rica and El Salvador, to create a diverse portfolio from the same farm. Understanding this helps you buy with intention.

What are the Key Challenges and Rewards of Honey Processing?

The reward is a uniquely marketable cup: it often wins over consumers who find washed coffees too acidic and naturals too wild. It offers a "best of both worlds" profile—sweetness and body without overpowering fermentation.

The challenge is entirely about risk management during drying. The sticky mucilage is a magnet for fungus and uncontrolled fermentation. It requires immaculate drying beds, perfect weather, and constant manual labor to turn the beans. A sudden rain can ruin a batch. This higher labor and risk is why honey process coffees often command a price premium over washed lots from the same farm. It represents a significant investment of skill and effort by the producer.

How Should You Roast and Buy These Coffees Differently?

From a buyer's and roaster's perspective, these two methods demand completely different approaches.

Buying Wet Hulled Coffees:

- Focus on Trust: Due to the higher risk of defects, you must buy from a trusted importer or exporter with rigorous grading. Sample extensively.

- Expect Variability: These coffees can vary more from bag to bag or year to year. Embrace it as part of their character.

- Perfect for Blending: Their bold, low-acid profile makes them a classic base for espresso blends, adding body and depth that cuts through milk.

Buying Honey Process Coffees:

- Clarify the "Color": Ask the supplier what type of honey process it is. A "red honey" from one farm can differ from another.

- Price Expectation: Be prepared to pay a premium for the additional labor and risk, especially for Red and Black honeys.

- Seek Clarity in Sweetness: The best examples have a clean, refined sweetness, not a muddy, over-fermented taste.

Roasting Implications:

- Wet Hulled: These beans are often less dense and have undergone more physical stress. They can roast faster and are more prone to tipping or scorching. Use a gentler, more gradual roast to develop their complex flavors without burning.

- Honey Process: The retained sugars caramelize during roasting. They can benefit from a slightly slower development phase to fully develop that sweetness without baking. Expect a different color progression than a washed bean.

Which Process Offers More Consistency for a Buyer?

For predictable, batch-to-batch consistency, a well-executed Honey Process from a professional farm tends to be more controllable. The environment is managed, and the process is intentional. Wet Hulling, by its nature and typical smallholder context, introduces more variables from climate and processing equipment, leading to greater, though often appealing, variability. If your brand requires absolute consistency, you need an importer who does severe quality selection on wet-hulled lots.

Can These Methods Be Applied Outside Their Traditional Regions?

This is a fascinating frontier. Honey Processing has been successfully adopted in coffee regions worldwide, from Brazil to Yunnan, as producers seek new flavor profiles. Wet Hulling, however, remains largely confined to its Indonesian birthplace. Its specific climate requirements and unique equipment setup make it difficult and often unnecessary to replicate elsewhere. It is a true regional signature, much like the terroir of a wine.

Conclusion

Wet Hulling and Honey Processing are both "semi-washed" in technical terms, but they are philosophical opposites. Wet Hulling is a forced march, a rapid drying solution born of necessity that yields a bold, earthy, and robust cup. Honey Processing is a deliberate stroll, a sweet and risky experiment in flavor crafting that yields a syrupy, clean, and complex cup.

For your business, the choice isn't about which is better, but about which tool delivers the flavor profile your customers desire. Understanding this difference empowers you to source with purpose, roast with strategy, and market with a compelling story.

While BeanofCoffee specializes in the pristine clarity of fully-washed Yunnan Arabica, our expertise extends to guiding you through the entire world of coffee processing. We help you understand how each method shapes the final product in your bag.

To explore how different processing methods can align with your product line, contact our sales lead, Cathy Cai. We can provide samples and detailed process explanations. Email cathy@beanofcoffee.com.