As a coffee buyer, you're constantly thinking about the stability of your supply chain. You hear about labor shortages, rising wages in coffee-growing countries, and the unpredictable nature of harvests. You're right to be concerned. These issues directly translate to higher prices and potential delays for you. So, when you hear about "automated harvesting," it probably sparks a mix of hope and skepticism. Can a machine really replace the skilled hands of a picker? And what does that do to the quality of the beans you buy?

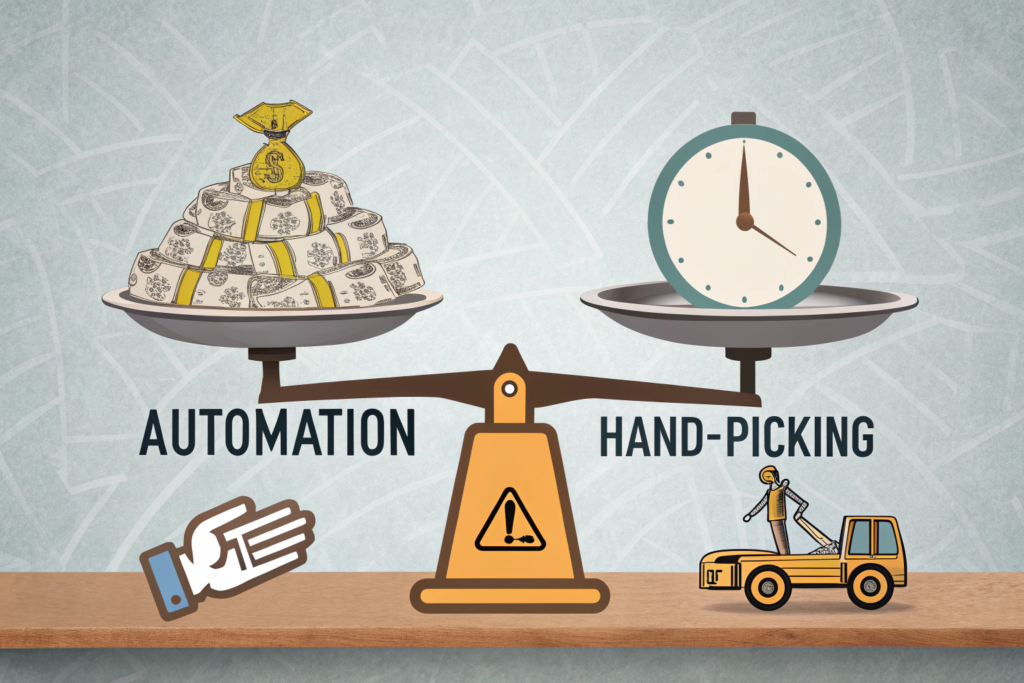

Honestly, the primary impact of automation on coffee harvesting is a dramatic reduction in labor costs and a significant increase in harvesting speed, which can help stabilize coffee prices. However, this efficiency often comes at the cost of selectivity, as machines typically strip-harvest both ripe and unripe cherries, potentially lowering the quality of the final crop if not managed properly. It's a classic trade-off between efficiency and quality.

On my own 10,000 acres here in Yunnan, this isn't a theoretical debate. It's a strategic decision we face every season. While much of our specialty-grade coffee is still hand-picked to ensure perfection, we are actively exploring and implementing automation on a larger scale. It's about finding the right balance to ensure we can provide you with a stable, high-quality, and cost-effective supply. Let's look at the real-world impact of these machines.

How do mechanical harvesters actually work?

It's easy to imagine a giant, clumsy robot tearing through a coffee plantation, but modern technology is far more sophisticated. Understanding the mechanics is key to understanding both the potential and the limitations of automated harvesting. These aren't just tractors; they are specialized pieces of agricultural engineering.

Most mechanical coffee harvesters work by straddling a row of coffee trees and using sets of vibrating fiberglass rods, or "beaters," to shake the branches. This vibration is calibrated to dislodge the ripe cherries, which fall onto a conveyor system at the base of the machine, while leaving most of the green, unripe cherries and the tree's foliage intact. The collected cherries are then transported into a holding bin.

Think of it like shaking an apple tree, but on a massive, more controlled scale. The principle is simple: ripe cherries are attached less firmly to the branch than unripe ones. The machine is designed to exploit this difference. The effectiveness of this process, however, depends heavily on the farm's layout and the type of coffee being grown. This is a major reason why farms like ours at Shanghai Fumao are designed with modern, wide rows to accommodate such technology.

What are the different types of harvesters?

There are two main types. The large, self-propelled over-the-row harvesters are the most common for large-scale operations, like those found in Brazil. They are massive machines that drive over the coffee rows. For smaller farms or those on steeper terrain, there are smaller, tractor-pulled harvesters or even handheld mechanical shakers. These handheld devices look like a long pole with a vibrating head, helping a single worker shake cherries loose much faster than by hand.

What is required for a farm to be "machine-harvestable"?

You can't just drive a harvester onto any old coffee farm. The plantation must be specifically designed for it. This includes:

- Flat or Gently Sloping Terrain: The large machines cannot operate on steep hillsides.

- Uniform Tree Spacing: Trees must be planted in straight, wide rows to allow the machine to pass.

- Pruning: Trees must be pruned to a specific height and shape to fit within the harvester's frame.

- Even Ripening: The coffee variety grown should ripen evenly to maximize the yield of ripe cherries in a single pass. This is why varieties like our Catimor are well-suited for this approach.

What are the economic benefits of automation?

The primary driver behind the push for automation is simple: economics. Hand-picking coffee is incredibly labor-intensive and is often the single largest expense in coffee production. As wages rise globally and labor becomes scarcer, the economic case for mechanization becomes undeniable for many large-scale producers.

The most significant economic benefit of automation is a drastic reduction in harvesting costs, which can be lowered by as much as 80-90% compared to manual labor. Mechanical harvesters can do the work of hundreds of pickers in a fraction of the time, leading to massive gains in efficiency and a more stable, predictable cost of production.

For a buyer like you, this is hugely important. When our production costs are stable, the price we can offer you is also more stable and less susceptible to the volatile labor market. This allows you to forecast your own costs with much greater accuracy. While the initial investment in the machinery is high, the long-term operational savings are a game-changer for the industry, especially for the large volumes of coffee that go into blends and everyday consumer products.

How does automation impact labor?

Harvesting is seasonal work. Finding, housing, and managing hundreds or even thousands of temporary workers for a few months each year is a massive logistical and financial challenge. Automation significantly reduces this dependency. It doesn't necessarily eliminate jobs entirely, as you still need skilled operators, mechanics, and a smaller crew for post-harvest sorting, but it transforms the nature of the workforce from a large, temporary crew to a smaller, more skilled, year-round team.

Can automation make coffee cheaper?

In the long run, yes. By lowering the cost of production for large-volume coffees, automation helps keep the price of mainstream coffee on the shelf affordable. It creates a more resilient supply chain that is less vulnerable to labor shocks. This doesn't mean all coffee gets cheaper—high-end, specialty micro-lots will likely always be hand-picked and command a premium. But for the reliable, consistent beans that form the backbone of the industry, automation is a key tool for cost control.

How does automation affect coffee quality?

This is the most critical question for a quality-focused buyer. The most skilled hand-picker has a brain, eyes, and gentle hands. They can select only the perfectly ripe cherries, leaving the unripe ones for a later pass. A machine, no matter how advanced, is less discerning. This is where the quality trade-off comes into play.

Automation's biggest negative impact on quality is its lack of selectivity. Mechanical harvesters inevitably collect a mix of ripe, overripe, and unripe cherries, along with some leaves and twigs. This mix, if not properly sorted, can lead to sour, astringent, and inconsistent flavors in the final cup.

However, this is not a deal-breaker. It simply shifts the quality control focus from the moment of picking to the post-harvest stage. Producers who use mechanical harvesters must invest heavily in sophisticated sorting technology to separate the good from the bad. At Shanghai Fumao, we understand that if we use mechanical harvesting, we must pair it with world-class sorting.

What is the "green bean problem"?

The presence of unripe, or "green," cherries in the harvest is the main issue. A single unripe bean can impart a sour, grassy, or "astringent" flavor to a brewed cup. While a few might not be noticeable in a large blend, a high percentage of them can ruin the entire batch. This is why post-harvest sorting is so critical for machine-harvested coffee.

How is machine-harvested coffee sorted?

Modern coffee mills use a multi-stage sorting process to clean up machine-harvested lots. This can include:

- Floatation Tanks: Ripe cherries sink while unripe ones and debris tend to float.

- Mechanical Sorters: Screens and shakers that separate beans by size and density.

- Optical Sorters: High-tech machines that use cameras and jets of air to analyze the color of each individual bean and blast away any that are unripe, discolored, or defective. These color sorters are an essential investment for any serious producer using mechanical harvesting.

What is the future of automation in coffee?

The technology is not standing still. The choice is no longer just "hand-picking vs. dumb machine." The future is about "smart farming," where data, robotics, and precision agriculture come together to optimize both efficiency and quality. The goal is to create a system that has the efficiency of a machine and the "brain" of a master picker.

The future of automation lies in combining robotics with artificial intelligence and sensor technology. We are moving towards a reality of autonomous, data-driven harvesters that can more accurately determine the ripeness of cherries, and drones that can map out plantations to identify which sections are ready for harvest. This will allow for more selective, targeted mechanical harvesting, closing the quality gap with manual picking.

This is the future we are investing in. Imagine drones flying over our plantations, creating a real-time "ripeness map." This data is then fed to an autonomous electric harvester that only works on the rows that have the highest concentration of ripe fruit. This isn't science fiction; it's the next logical step in the evolution of precision agriculture. It's a future that promises sustainability, efficiency, and high quality, all at the same time.

What is selective harvesting?

The holy grail of automated harvesting is "selective harvesting"—a machine that can pick only the ripe cherries. While current technology isn't quite there yet for large-scale use, several companies and universities are developing robotic arms with cameras and AI that can identify and pick individual cherries. This technology is still very expensive and slow, but it shows the direction the industry is heading for high-value specialty coffees.

How will this impact the coffee world?

This new wave of automation will likely create a more tiered coffee market. The vast majority of coffee will be harvested by increasingly smart and efficient machines, ensuring a stable and affordable global supply. At the very top end of the market, for the most exclusive and expensive micro-lots, the human touch of a skilled picker will remain a celebrated and valuable part of the story. This technological advancement will ensure the long-term sustainability of the entire industry, from the everyday cup to the competition-winning single origin.

Conclusion

The impact of automation on coffee harvesting is a complex story of trade-offs. It offers a powerful solution to the economic pressures of labor costs and shortages, promising a more stable and efficient supply chain. However, this efficiency comes with a significant challenge to quality control, demanding a much greater investment in post-harvest sorting to eliminate unripe and defective beans. The future is not a simple choice between man and machine, but a smarter integration of both. By leveraging data, AI, and robotics, we can move towards a future that captures the best of both worlds: the efficiency of automation and the selectivity of a master picker.

As your partner in sourcing, we are committed to navigating this evolving landscape with you. Whether you need the consistent quality of our machine-harvested and optically-sorted lots or the perfection of our hand-picked specialty grades, we have the scale and technology to meet your needs. If you're ready to work with a forward-thinking supplier who is invested in the future of coffee, please reach out. Contact our coffee specialist at cathy@beanofcoffee.com to discuss how we can build a resilient and high-quality supply chain together.